AGENDA

Ordinary meeting of the

Nelson Regional Sewerage Business Unit

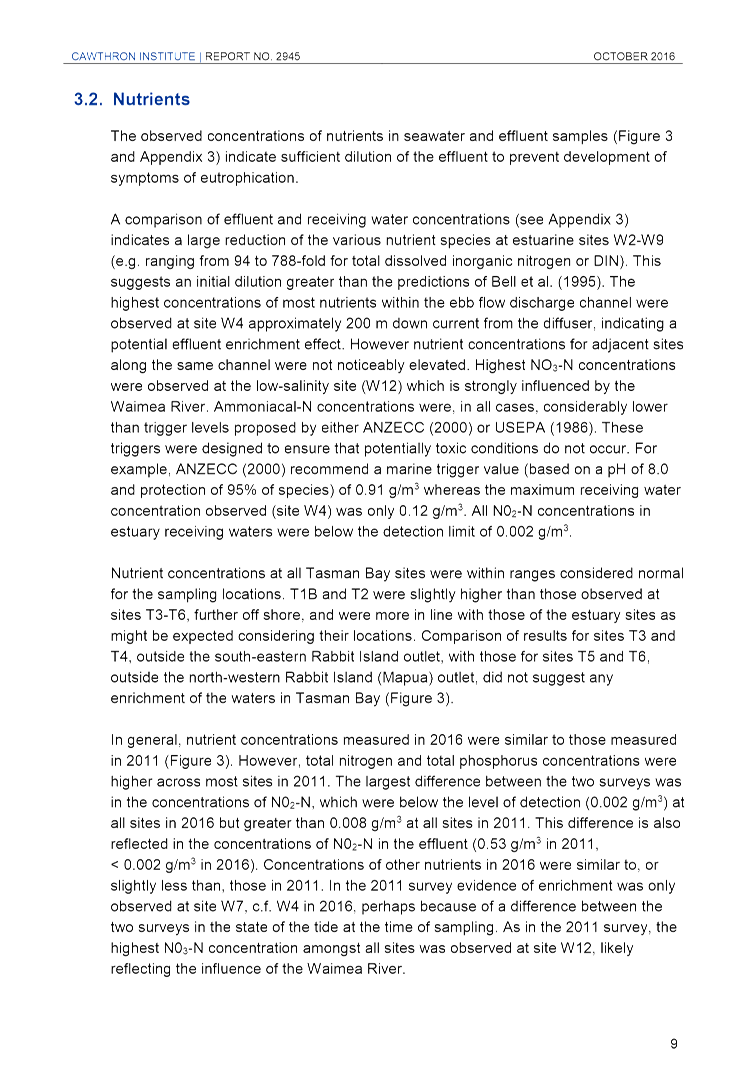

Friday 9 December 2016

Commencing at 1.00pm

Ruma Mārama, Floor 2A

Civic House

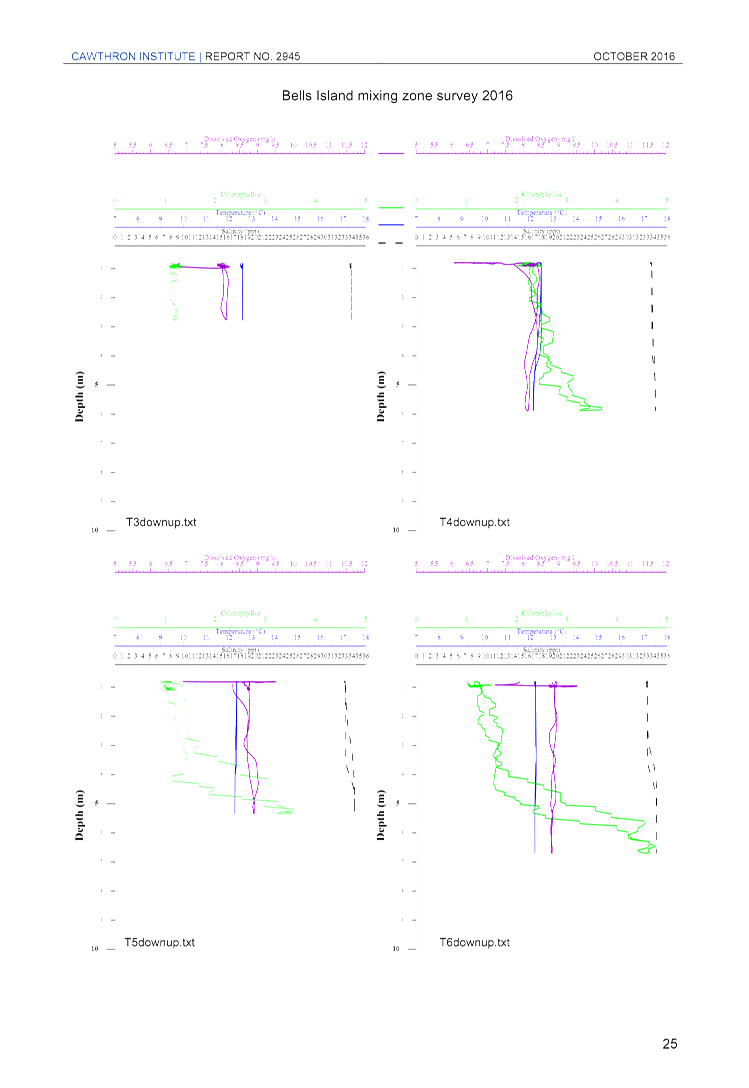

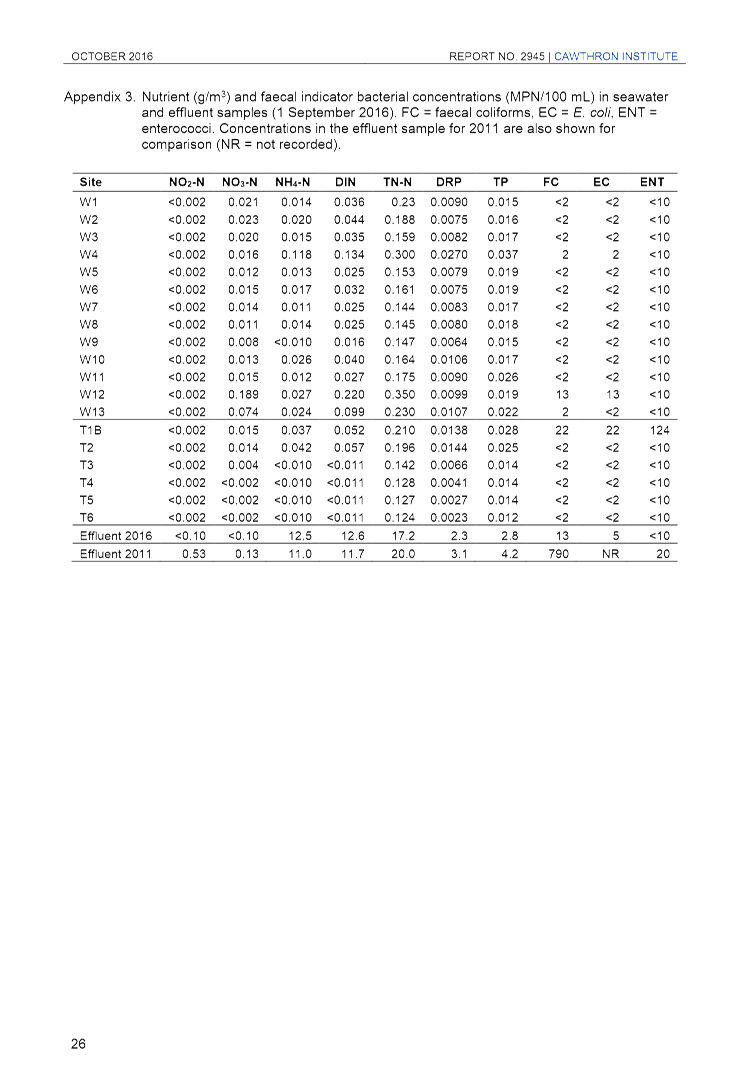

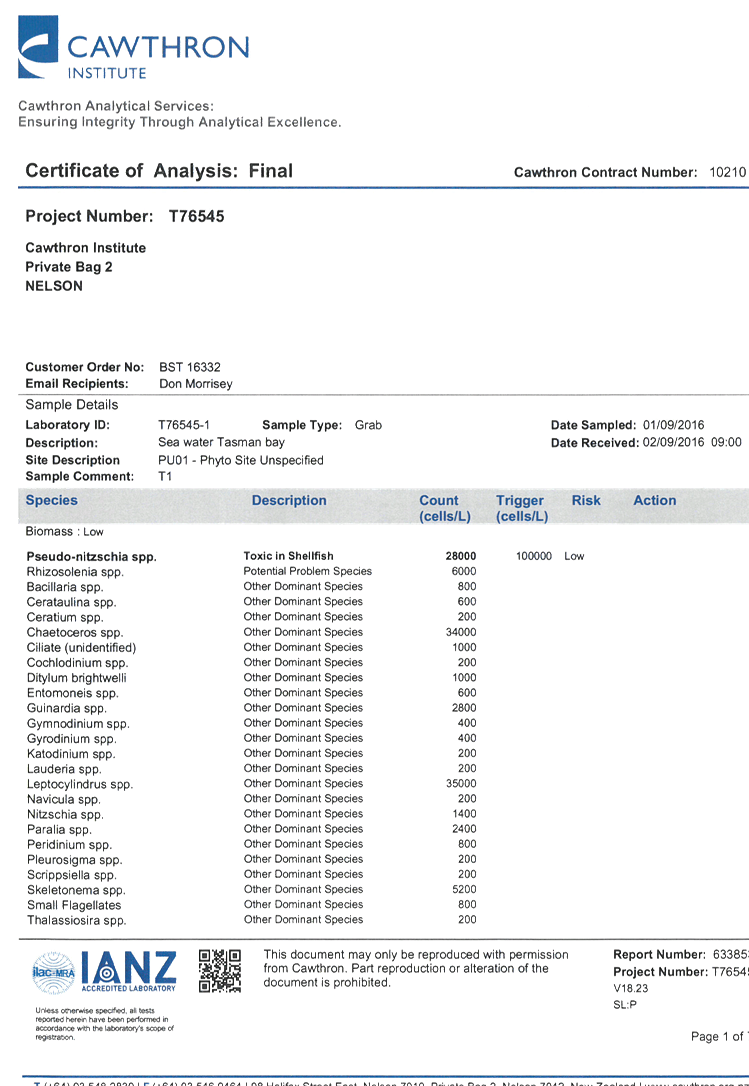

110 Trafalgar Street, Nelson

Membership: Nelson City Councillors Stuart Walker and Tim

Skinner, Tasman District Councillor Kit Maling, and Michael Higgins

Representatives: M Hippolite (Iwi Representative) and P

Wilson (Industry Customers Representative)

Guidelines for councillors

attending the meeting, who are not members of the Committee, as set out in

Standing Orders:

·

All councillors, whether or not they are members of the

Committee, may attend Committee meetings (SO 2.12.2)

·

At the discretion of the Chair, councillors who are not Committee

members may speak, or ask questions about a matter.

·

Only Committee members may vote on any matter before the

Committee (SO 3.14.1)

It is good practice for both Committee members and

non-Committee members to declare any interests in items on the agenda.

They should withdraw from the room for discussion and voting on any of these

items.

Nelson Regional Sewerage Business Unit

9

December 2016

Page

No.

Apologies

1. Confirmation

of Order of Business

2. Interests

2.1 Updates

to the Interests Register

2.2 Identify

any conflicts of interest in the agenda

3. Public

Forum

4. Appointment

of Chairperson

An officer will assume the chair

and call for nominations from the Nelson Regional Sewerage Business Unit for

the appointment of a Chairperson.

Recommendation

That the Business Unit

Appoints

[ name ] as

Chairperson of the Nelson Regional Sewerage Business

Unit.

4. Appointment

of Deputy Chairperson

The Chairperson will call for

nominations from the Nelson Regional Sewerage Business Unit for the appointment

of a Deputy Chairperson.

Recommendation

That the Business Unit

Appoints

[ name ] as

Deputy Chairperson of the Nelson Regional Sewerage Business

Unit.

5. Annual

Report 2015/16

At the

time the agenda was prepared, the Annual Report 2015/16 had not yet been

received back from Audit New Zealand. Officers will provide an update at the

meeting.

6. Bell

Island Wastewater Treatment Plant - Pond Sludge Management 6 - 17

Document number R5951

Recommendation

That the

Business Unit

Receives

the report Bell Island Wastewater Treatment Plant - Pond Sludge Management

(R5951); and

Approves

proceeding with engaging Gurney Environmental for the supply and delivery to

Nelson of 9 (nine) Accel-o-Fac series three aerator/mixers in Pond F2 up to 50%

of the value of $280,000 (excl GST); and

Approves

the investment of up to $60,000 to install the 9 (nine) Accel-o-Fac series

three aerator/mixers in Pond F2; and

Approves

the negotiation of a variation to the Operation and Maintenance contract for

the installation of nine Accel-o-Fac aerator/mixers in facultative pond F2 and;

Approves

funding for the upgrade of the maturations ponds and desludging of the ponds in

the 2015/16 and 2016/17 Business Plans be utilised for this initiative; and

Approves

the monitoring of effluent quality in chambers C4, C5 and C6 to assess the

performance of upgraded pond (F2) compared to the other two facultative ponds

(F1 and F3); and

Requests

that the outcome of the monitoring be reported back to the NRSBU for approval

prior to the remaining 50% payment being made to Gurney Environmental.

7. Bell

Island Wastewater Treatment Plant - Electrical Power Business Continuity

Assessment 19 - 28

Document number R6834

Recommendation

That the Business Unit

Receives the report Bell Island

Wastewater Treatment Plant - Electrical Power Business Continuity Assessment

(R6834); and

Notes

the offer from Network Tasman to fund 50% of the capital cost ($447,000) of

installing a second cable to the Bell Island Wastewater Treatment Plant has

been declined; and

Approves

adding the option of including the installation of permanent backup generation

for the Inlet Structure and Discharge Pump (250 kVa) in the draft Business Plan

2017/18.

8. General

Manager's Report 29 - 136

Document number R6816

Recommendation

That the Business Unit

Receives the General Manager's

Report (R6816) and its

attachments (A1649724, A1665105, A1645078, A1436459, A452094, and A1664757);

and

Approves

the Draft Business Plan 2017/18 (A1664757).

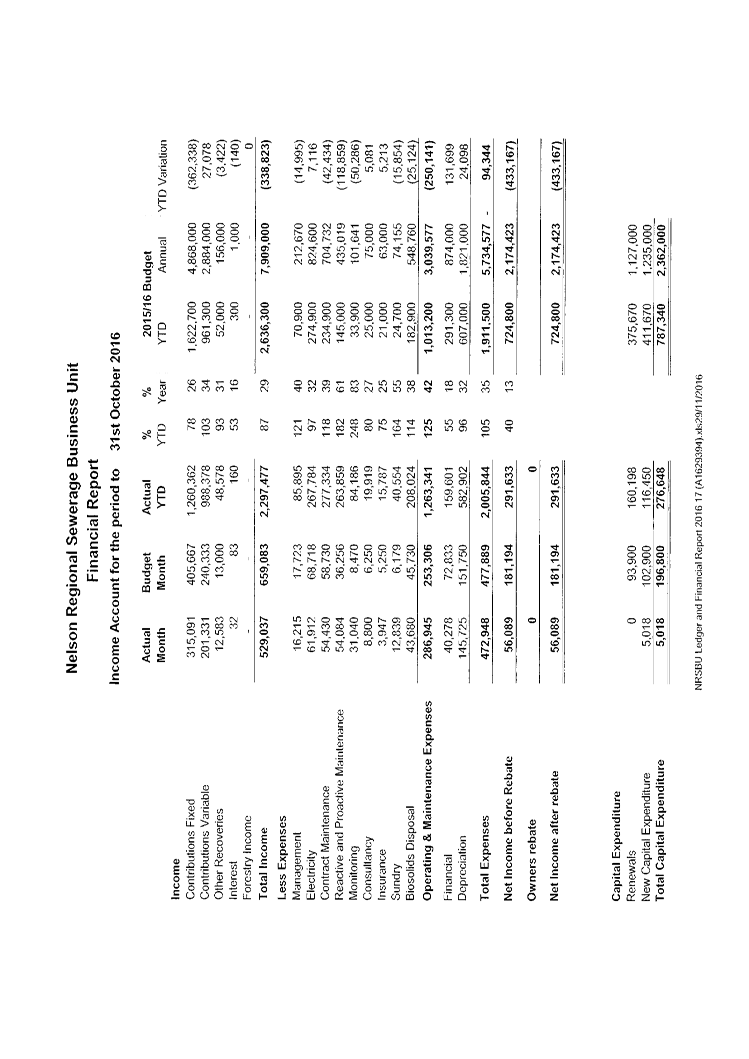

9. Financial

Report 137 - 139

Document number R6885

Recommendation

The the Business Unit

Receives the Financial Report

(R6885) and its attachment

(A1629394).

|

|

Nelson Regional Sewerage Business Unit

9 December 2016

|

REPORT R5951

Bell

Island Wastewater Treatment Plant - Pond Sludge Management

1. Purpose of Report

1.1. To

review the options of dealing with the sludge accumulation in the maturation

and facultative ponds at the Bell Island Wastewater Treatment Plant (WWTP).

2. Recommendation

|

That

the Business Unit

Receives

the report Bell Island Wastewater Treatment Plant - Pond Sludge Management

(R5951); and

Approves

proceeding with engaging Gurney Environmental for the supply and delivery to

Nelson of 9 (nine) Accel-o-Fac series three aerator/mixers in Pond F2 up to

50% of the value of $280,000 (excl GST); and

Approves

the investment of up to $60,000 to install the 9 (nine) Accel-o-Fac series

three aerator/mixers in Pond F2; and

Approves

the negotiation of a variation to the Operation and Maintenance contract for

the installation of nine Accel-o-Fac aerator/mixers in facultative pond F2

and;

Approves

funding for the upgrade of the maturations ponds and desludging of the ponds

in the 2015/16 and 2016/17 Business Plans be utilised for this initiative;

and

Approves

the monitoring of effluent quality in chambers C4, C5 and C6 to assess the

performance of upgraded pond (F2) compared to the other two facultative ponds

(F1 and F3); and

Requests

that the outcome of the monitoring be reported back to the NRSBU for approval

prior to the remaining 50% payment being made to Gurney Environmental.

|

3. Background

3.1. The

Bell Island WWTP includes 3 facultative oxidation ponds (F1, F2 & F3) and 2

maturation ponds (M1 & M5). These ponds are an important part of the

treatment process in that they allow natural processes to treat the

wastewater. Part of this natural process involves the settlement of

sludge to the base of the ponds.

3.2. The

ponds have aerators as follows;

· F1

– 1 No. Hamilton brush aerator/mixer plus 4 No. Aire-O2 Aspiration

Aerators.

· F2

– 1 No. Hamilton brush aerator/mixer plus 4 No. Aire-O2

Aspiration Aerators.

· F3

– 1 No. Hamilton brush aerator/mixer plus 3 No. Aire-O2

Aspiration Aerators.

· M1 and

M5 – no aerators.

3.3. All

the ponds experience a build-up of sludge that in time increasingly compromises

their effectiveness. It has been 20 plus years since the last desludging

was undertaken.

3.4. The

NRSBU Business Plan 2016/17 has listed capital projects to upgrade the performance

of the WWTP including the proposal to de-sludge the ponds. Table 3.4

outlines the capital projects related to the pond efficiency improvements;

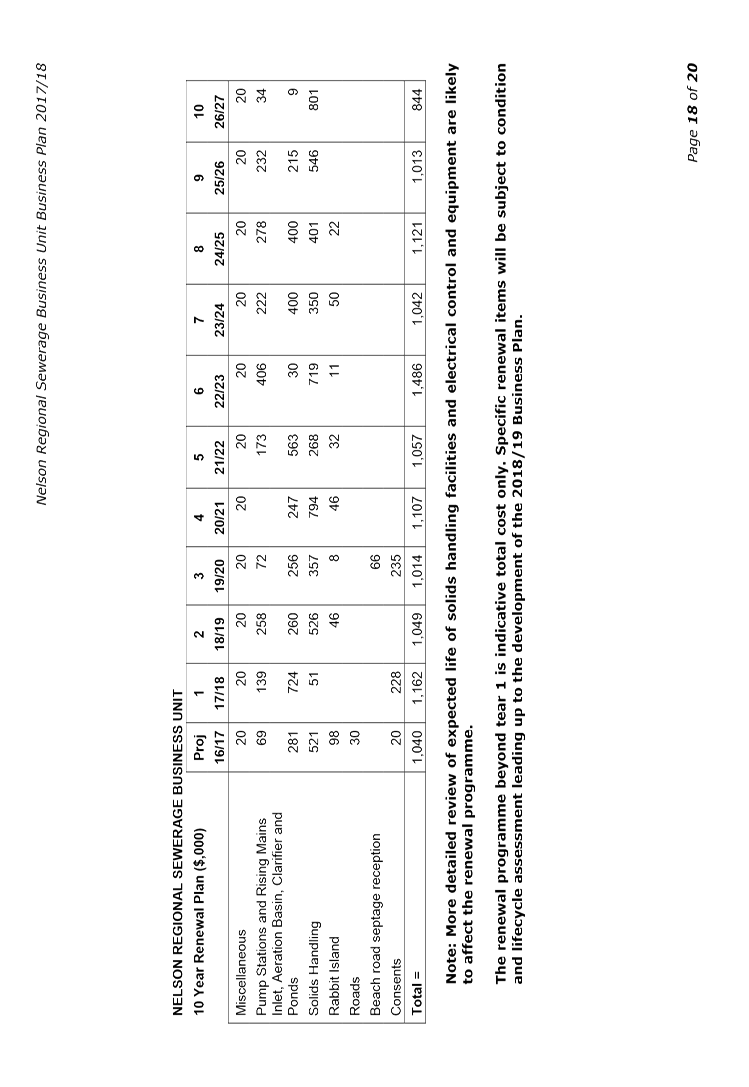

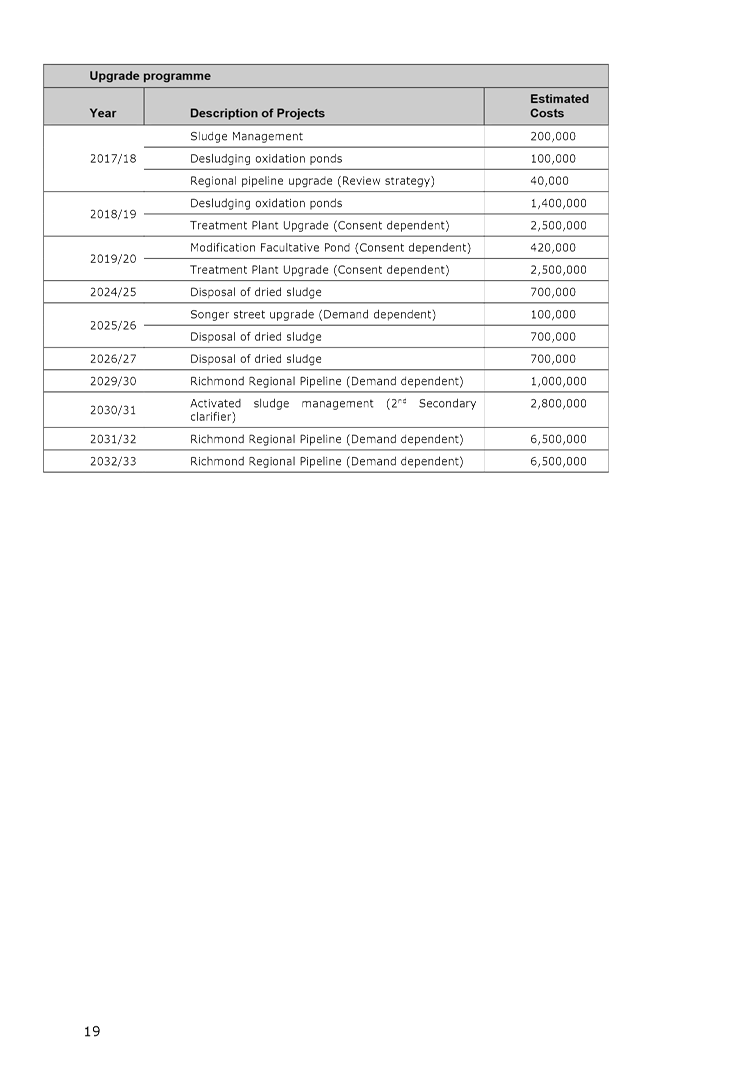

Table 3.3 – Capital Upgrade Projects 2016/17 Business Plan

|

Year

|

Description of Projects

|

Estimated Costs

|

|

2016/17

|

Carry forward from 2015/16:

Desludging Ponds (Option Study)

|

40,000

|

|

Modification pond M1 (The

installation of the curtains in M1 will create directional flow through the

pond which will result in improved treatment and removal of algae. The work

will only commence once the effectiveness of improvement in M5 has been assessed)

|

140,000

|

|

Carry forward from 2015/16:

Modifications pond M5

|

140,000

|

|

Desludging oxidation ponds (The

desludging will be carried out over two financial years)

|

200,000

|

|

2017/18

|

Desludging oxidation ponds (The

desludging will be carried out over two financial years)

|

1,400,000

|

|

2018/19

|

Modification pond F3 (The

installation of the curtains in F3 will create directional flow through the

pond which will result in improved treatment and removal of algae. The work

will only commence once the effectiveness of improvement in M1 &M5 has

been assessed)

|

140,000

|

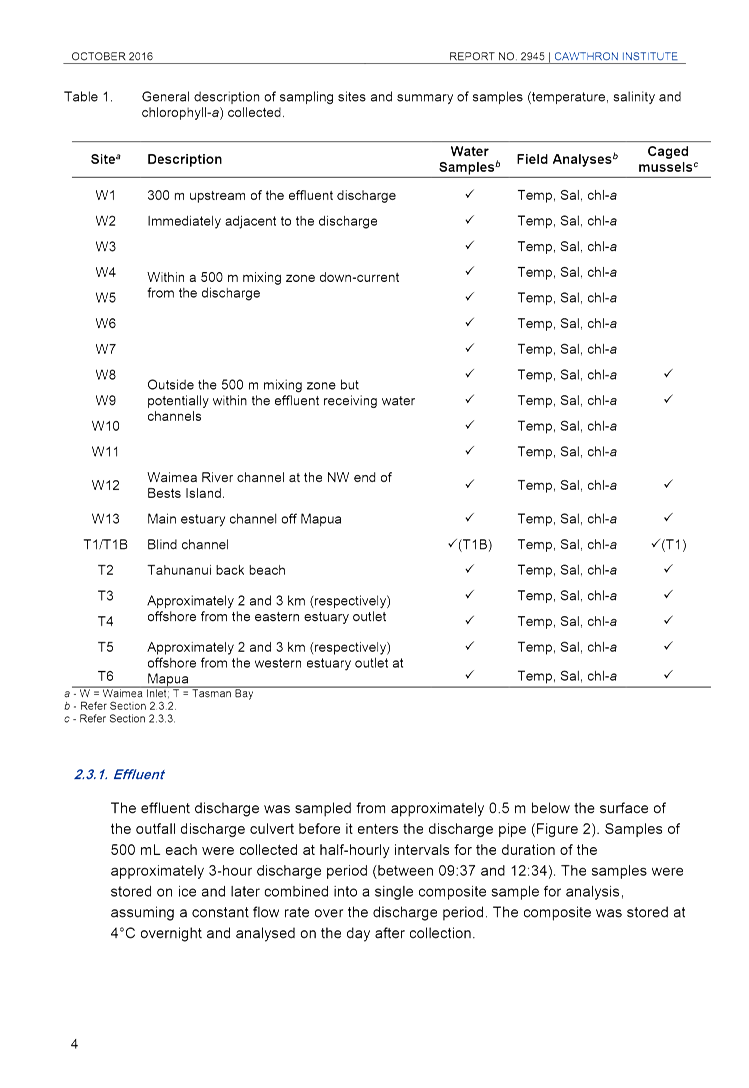

4. WWTP – Pond Sludge Management

4.1. Over

recent years there has been a gradual increase in carbonaceous biological

oxygen demand (CBOD) in the final discharge effluent from the WWTP.

Although this increase is still within the consented limits for the discharge,

it does indicate a decrease in retention times within the ponds. This

could be attributed to the increasing sludge accumulation.

4.2. Recent sludge surveys have confirmed the increased

accumulation. They have also confirmed that the sludge is only partially

digested. This is not surprising as the current aeration system was not

designed to provide sufficient aeration and mixing. The original

intention was to allow the ponds to operate naturally with some minor aeration

and mixing capability introduced in 1992 to enhance performance.

4.3. The NRSBU has anticipated the need to deal with the

accumulated sludge as outlined in its Business Plan 2016/17 and Table 3.3

above.

4.4. There are several options that could be implemented to

deal with the accumulated sludge in the ponds. These are summarised as

follows;

· Mechanical

Removal – remove sludge using specialised equipment and either place in

geobags or dispose of in a consented manner (either on site or at

approved landfill);

· Increased aeration and mixing – additional

aeration and mixing can accelerate the digestion of sludge accumulated in the

ponds.

5. WWTP - Pond

Performance

5.1. The

ponds are currently operating well, however a review of the aeration and mixing

indicates that there is an opportunity to improve treatment efficiency.

Although sludge will still be a by-product, initial assessments suggest that

with improved aeration and mixing there is likely to be better sludge digestion

and longer lead times between de-sludging.

5.2. Recent

condition and performance inspections have confirmed that the Aire-O2 and

Hamilton aerators are at the end of their useful lives. Whilst not

requiring urgent replacement these aerators are now high maintenance. The

Aire-02’s parts are becoming difficult to source and the

motors are getting to the point where rewinding is increasingly expensive due

to the amount of wear etc.

5.3. It

is therefore prudent to either consider replacing them as is, or reviewing the

types and layout of aerators to improve the efficiency of the ponds.

5.4. The

replacement cost of the current aeration/mixing equipment is $67,000 per

facultative pond (around $200,000 for the three facultative ponds).

6. Sludge Removal

Options

6.1. The

NRSBU has been assessing the options to deal with the accumulated sludge in the

ponds. This has included considering improvements in the aeration and

mixing parameters which potentially have an impact by reducing sludge

production and increasing sludge digestion. Some of the options claim to

reduce levels of accumulated sludge and claim to keep sludge at manageable

levels that will never require physical removal. These claims need to be

substantiated.

6.2. In

general conventional sludge removal option is only focused on sludge removal

and does not improve mixing or aeration. The other options are primarily

focused on aeration and mixing and any improvement in sludge digestion is

consequential.

6.3. The

conventional sludge removal is required every 20-25 years depending on the

loadings and pond treatment effectiveness. The cost of this is around

$1,400,000 for the three FOPs each time. It requires a consent to dispose

of the sludge and this can occur either in an appropriate manner on site or at

another consented off-site location e.g. landfill (The cost of haulage and

disposal to landfill is not included in this estimate).

6.4. The

installation of comprehensive aeration/mixing equipment on all three FOPs is

estimated at around $1,200,000. The annual operating cost of these vary

as some equipment utilise wind power, others utilise solar energy and others

electrical power. The wind power and solar energy equipment can have

backup power installed. The annual operating costs are estimated as

follows;

· Current

system $26,500/year

· Wind

power alone $2,200/year

· Wind power

with backup electrical power $4,220/year

· Solar

energy alone $500/year

plus $7,000 every seven years for replacement of batteries

· Grid-Bee

electrical powered misers $7,500/year

6.5. The

conventional sludge removal does not improve aeration/mixing whereas the

improved aeration mixing does.

7. Aeration/Mixing

and Sludge Management Proposals

7.1. The

sludge removal proposals are outlined as follows;

· Conventional

Sludge Removal – utilising mechanical equipment to remove sludge from

the ponds;

· Improved

Aeration/Mixing - Accel-o-Fac equipment which may improve sludge digestion

and reduce accumulated sludge levels;

· Improved

Aeration/Mixing - Solar/Grid-Bee Equipment which may improve sludge

digestion and reduce accumulated sludge levels.

8. Conventional

Sludge Removal

8.1. The

most common method to remove sludge from ponds in New Zealand is the use of a

dredge.

8.2. The

sludge is generally thickened through the application of polymer with effluent

diverted back to the pond and the thickened sludge placed in a contained area

(could include a geobag or a sludge lagoon).

8.3. The

sludge is then allowed to dewater naturally.

8.4. Once

the sludge has reached a specified consistency it is disposed of through land

application or landfilling.

9. Improved

Aeration/Mixing - Accel-o-Fac Aerators/Mixers - Gurney Environmental

Overview

9.1. There

is a company that supplies wind powered aerators. The company is called

Gurney Environmental (GE) and a representative visited the WWTP in April

2016. GE has developed a proposal for the NRSBU. The proposal

focuses on the eventual installation of wind generated Accel-o-Fac

aeration/mixing equipment in all the ponds. GE believes that this

equipment will not only improve the mixing and aeration of the ponds, but also

reduce the volumes of accumulated sludge.

9.2. GE

has analysed the treatment plant data to evaluate the current performance of

the pond system. It also analysed the wind profile at Nelson airport and

translated that across to what would occur at Bell Island. It confirms

the wind consistency and strength are sufficient to effectively power the

Accel-o-Fac aerators/mixers.

9.3. Based on this analysis the

wind generated Accel-o-Fac aerators/mixers are designed to:

· Provide

a cost effective upgrade that will make use of existing assets and improve the

treatment capabilities and capacity of the treatment plant.

· Eliminate

short circuiting from inlet to outlet.

· Distribute

loads evenly through the ponds.

· Reactivate

and increase digestion of the accumulated sludge in the ponds.

· Increase

Dissolved Oxygen levels through the ponds to provide improved BOD and TSS

removal, and nitrification.

· Increase

the robustness of the wastewater treatment system so that it will accommodate

increased loads, and wide swings in flow and loading without operator

attention.

· Minimise

and/or eliminate odour.

· Deliver

maximum processing for the minimum total-life-cost and the least operator

attention.

The Gurney Environmental Proposal

9.4. Gurney Environmental has proposed

installing its equipment in all five ponds. This comprises 33 Accel-o-Fac

Aerators at a capital cost of approximately $1,250,000 excl GST.

9.5. In proposing this as the ultimate

intention, GE has proposed a progressive implementation with a risk-share approach

until the effectiveness of the aerators/mixers has been confirmed by the

NRSBU. GE has suggested that the equipment be installed on F2 pond

initially with the NRSBU only funding 50% of the cost until the stated

performance has been achieved.

9.6. The scope of this initial

investment is as follows. GE shall:

· Supply

and deliver 9 (nine) Accel-o-Fac series 3s aerators;

· Supply

mooring system;

· Send

an engineer to oversee the installation;

· Total

cost of $280,000 (UK Pound 152,000)

9.7. The

NRSBU shall:

· Pay GE

50% of the equipment and shipment cost of $140,000 (UK Pound 76,000) upfront

with the balance due when the NRSBU is satisfied that the Accel-o-Fac system is

providing the benefits promised.

· Be

responsible for the installation cost to be carried out by a local contractor.

(Estimate NZ$60,000)

· Install

the aerators in accordance with the design in pond F2.

· Evaluate

the performance of pond F2.

9.8. The total estimated cost of

implementing the proposal is estimated at $340,000 but

is subject to exchange rates and actual confirmed construction costs. Initially

the NRSBU will need to fund around $200,000 and pay the balance to GE as and

when performance is confirmed.

9.9. GE expect

the following improvement to occur with the Accel-o-Fac aerators:

· The

sludge level will drop by 762mm (Two and a half feet) and result in a 40%

decrease in the volume of sludge in the bottom of the pond over time.

· Stabilisation

of the sludge blanket level will be observed within a 12 month period.

· Noticeable

pond effluent improvements within one month of installation.

Proposed Performance Assessment

9.10. While the promised

improvements might appear speculative it is not difficult to measure the

performance of the upgraded pond compared to the performance of the other two

ponds.

9.11. The

COD, CBOD, Total Nitrogen, Total Phosphorous and suspended solids are monitored

in the discharge chambers of the facultative ponds so any improvements can

easily be assessed.

9.12. A

sludge survey programmed for November 2016 will be delayed to provide

comparative performance based on the June 2014 pond survey and other surveys

completed in the past four years. Any changes to the sludge blanket can

be benchmarked against previous sludge survey results.

9.13. Whilst poor management of loads can distort

the outcomes, GE is confident that it is not in the

interest of the NRSBU to manipulate the outcome of the process and is therefore

prepared to share the risk with the NRSBU to the extent that the payment of the

remainder of the contract value will be at the discretion of the NRSBU.

Due Diligence on the Proposal

9.14. Gurney Engineering provided a number of case studies that

demonstrate projects implemented worldwide achieved the outcomes stated in their proposal. A literature study and assessment of

the documentation provided support their proposal.

9.15. Inverloch

Treatment Plant, Victoria Australia – has installed and has been

trialling a Accel-o-Fac unit in a pond at the Inverloc treatment plant for the

last two years. It has installed another unit at another treatment plant

following part evaluation of the first unit 18 months later.

· The

Council reported that the units installed achieved a 20% increase in Dissolved

Oxygen (DO) allowing them to turn a 22kW aerator off for the greater part of

the year and maintaining the required pond performance.

· It

continues to run the 22kW aerator as a precaution during the peak loading

periods to supplement DO transfer to the ponds (Seasonal peak load resulting

from influx of visitors into the area).

· These

aerators generated significant energy savings compared to all the other

aerators trialled.

· The

units are easy to operate and maintain.

· The

construction is high quality and the aerators are considered more durable than

alternatives considered.

9.16. South

Gippsland Water reported their findings relating to the use of wind

generated Accel-O-Fac mixers to the 78th Annual WIOA Victorian Water

Industry Operation Conference. It reported that these mixers provide:

· More

cost effective solution than other systems considered. (Solar powered systems

were found to be significantly more expensive than wind generated systems)

· Energy

saving allows for 6 year pay-back period.

· Did

not require installation of 0.55kW backup motor.

· Dissolved

oxygen levels in the pond improved significantly.

· Easier

and less maintenance.

· Improved

effluent quality.

· Lower

Health and Safety risks associated with servicing.

9.17. It is apparent that efficiency gains in

treatment have been made at the different locations

where Accel-o-Fac aerators were installed. Improved DO transfer throughout the

water column in the ponds contribute to conditions

required to optimise bacterial activity in the ponds.

9.18. Many of the case studies report that sludge

is stabilised in the ponds to the effect that desludging of ponds will not be

required. In some instances the ponds have been operational for more than

40 years with no requirement to desludge these ponds.

9.19. Reduction of sludge blanket of two and a

half feet is reported in some of the case studies.

10. Solar/Grid-Bee - Iguana

Water Solutions

10.1. SolarBee,

a subsidiary of the Novasys Group in the United States of America. SolarBee has

provided quotes for a solar powered and grid system that will provide optimal

pond conditions for pond F2.

10.2. Based

on the current pond parameters SolarBee provided quotes for a solar powered and

grid powered mixing system through their agents in Australia, Iguana Water

Solutions. The SolarBee design consists of a 5 No. machines at a total cost of

$500,000 (solar) and $335,589.56 (grid) shipped to Bell Island and delivered to

Nelson. The final cost subject to exchange rate changes.

10.3. Installation

and connection to electrical grid, where required, are at the cost of the

NRSBU. This is estimated to cost around $60,000 for the five units.

10.4. The

annual operating costs are estimated to be around $20-22,000 per annum.

The savings in power costs for the solar models are absorbed in depreciation on

their greater value.

10.5. The

SolarBee Engineers claim that with SolarBee circulation in F2, the sludge

blanket should even out and start digesting at a much faster rate in a matter

of months. It claim that many of “their customers have never had to

consider dredging again after installing the machines, even those with severe

sludge buildup issues before installation”.

11. Assessment of Proposals

11.1. Opus

International Consultants (Opus) have undertaken a high level assessment of the

Accel-o-Fac proposal. It has indicated that this technology that has not

been implemented widely, however its aeration and mixing focus would improve

pond effectiveness and efficiency. It has reservations about the sludge

management claims but has recommended that the equipment is

worthy of a trial.

11.2. The

following table 11.2 outlines the respective annual operating estimates for

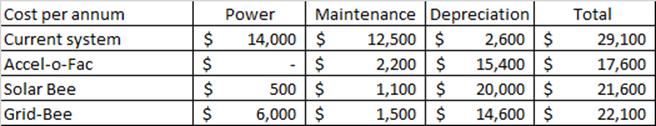

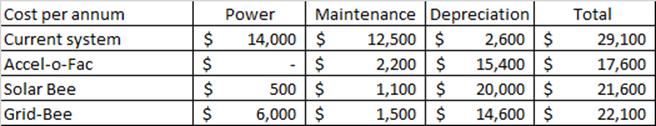

each of options in pond F2.

Table 11.2 –

Annual running for upgraded Facultative Pond F2

11.3. This

table shows that the current system has the highest annual operating costs and

that the Accel-o-Fac option has the lowest annual operating estimates.

11.4. The

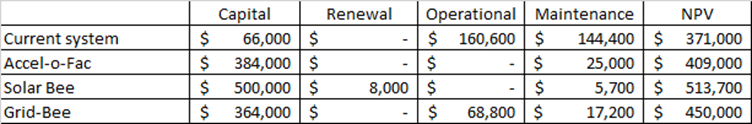

Net Present Value (NPV) for each of the options as installed in Pond F2 has

been calculated. These NPV values have been calculated over 50 years at a

discount rate of 6%. They essentially give an indication of the whole of

life costs for infrastructure by including the capital and renewal costs,

operational costs, maintenance costs and deprecation over the 50 year

period. The results are outlined in Table 11.4.

Table 11.4 -

Net present value for Facultative Pond F2 upgrade

11.5. The

NPV results indicate that the current system has the lowest NPV ($371,000) with

the next highest NPV being the Accel-o-Fac option ($409,000). Although

this table compares the value of each option in economic terms, it does not

account for the improved pond performance the other options would bring.

If additional aerators and/or mixers were installed to the current system then

it is very likely that the NPV would increase above the other options.

11.6. Accel-o-Fac

and Solar Bee engineers claim that the implementation of the proposed improvements

could delay the removal of sludge from the ponds indefinitely. This would

bring a significant saving as the estimated $1.4 million every 20-25 years

could be either delayed or, if the claims are substantiated, may not need to be

undertaken.

11.7. It

is therefore proposed that some of the funding set aside for the de-sludging of

the ponds over the next 2 years be utilised to fund the installation of

aerators/mixers in Pond F2 initially. The NRSBU can then assess the

effectiveness of this option in managing the sludge before committing to

further investment in the other ponds.

12. Potential

Benefits of Implementing Aeration/Mixing Proposal

12.1. If

the installation of aeration/mixing equipment is implemented and the improved

treatment is achieved this will provide the following benefits:

· Extend

the useful life of pond F2;

· Provide

an opportunity to evaluate implementing aerator/mixing equipment in all 5

ponds;

· Avoid

having to undertake an environmental analysis and obtaining consents for sludge

disposal;

· Improve

the quality of the effluent discharged from the WWTP;

· Result

in significant cost savings by deferring conventional sludge removal;

· Provide

the opportunity to further divert load away from the aeration basin.

13. Practical

Installation of Aeration/Mixers Option

13.1. Although there is confidence that the

aerator/mixing option will provide adequate DO to the ponds it is considered

prudent to retain the current aerator system for use as and when required

(especially so during winter months when available wind is much less than

during the rest of the year).

13.2. Once the aeration/mixing options has been

fully evaluated and implemented, and the anticipated improvements

substantiated, the current aerator equipment could be removed permanently.

This alone would decrease electricity use by approximately $13,000 per pond per

year and remove the need for their replacement in the future.

14. Consultation

14.1. The NRSBU could invest the allocated funding

and still comply with its objectives in its Business Plans for the improvement

of the ponds.

14.2. The changes proposed are not likely to have

any detrimental environmental effects that could affect the public.

15. Conclusion

15.1. The implementation of the aeration/mixing

option as proposed by Gurney Environmental will improve the treatment

efficiency of the ponds. This will also improve the digestion of

sludge. The scale and extent of sludge digestion and particularly in

treating the sludge already accumulated is less known. However,

indications are that it will have a positive affect and could defer the need

for conventional sludge removal indefinitely.

15.2. Gurney Environmental has accepted that the

NRSBU would be taking a risk implementing the proposal. GE has offered a

50% investment until the effectiveness of its proposal is substantiated.

If the NRSBU does substantiate the claims then it has the discretion to pay the

balance to GE.

15.3. The results of the project will provide the

NRSBU with information required to consider whether the conventional removal of

sludge is warranted to the same extent as originally envisaged.

15.4. The NRSBU can be reasonably confident that

the installation of the aerators/mixers in Pond F2 will result in a beneficial

outcome for both the efficiency and effectiveness of the pond and could enhance

the digestion of the accumulated sludge.

Richard

Kirby

Consulting

Engineer

Attachments

Nil

|

Important considerations for decision making

|

|

1. Fit

with Purpose of Local Government

This project fits in with the purpose of local

government as it contributes to meeting the current and future needs of

communities for good-quality local infrastructure and local public services.

|

|

2. Consistency

with Community Outcomes and Council Policy

This report is in line with the objectives of the

Nelson Regional Sewerage Business Unit in the provision of cost-effective

collection and treatment of wastewater.

|

|

3. Risk

The risks related to improvements to mixing in

facultative pond F2 are outlined in the report and the risks associated with

the recommended option have been highlighted and dealt with.

|

|

4. Financial

impact

The project will be funded from budgets approved in

the 2016/17 Business Plan and carry overs from the 2015/16 Business Plan

|

|

5. Degree

of significance and level of engagement

This matter is of low significance because it

relates to enhancing the business continuity for the wastewater treatment

plant operations.

|

|

6. Inclusion

of Māori in the decision making process

Consultation with Maori occurred as part of the

Draft Annual Plan 2016/17 process.

|

|

7. Delegations

The Committee has the responsibility for considering

the backup power supply as part of management of the Nelson Regional Sewerage

Business Unit and report to Council through its draft Business Plan 2017/18.

|

|

|

Nelson Regional Sewerage Business Unit

9 December 2016

|

REPORT R6834

Bell

Island Wastewater Treatment Plant - Electrical Power Business Continuity

Assessment

1. Purpose

of Report

1.1 To

review and assess business continuity requirements and options for the supply

of electricity to the Bell Island Wastewater Treatment Plant (WWTP)

2. Recommendation

|

That the Business Unit

Receives the report Bell Island

Wastewater Treatment Plant - Electrical Power Business Continuity Assessment

(R6834); and

Notes

the offer from Network Tasman to fund 50% of the capital cost ($447,000) of

installing a second cable to the Bell Island Wastewater Treatment Plant has

been declined; and

Approves

adding the option of including the installation of permanent backup

generation for the Inlet Structure and Discharge Pump (250 kVa) in the draft

Business Plan 2017/18.

|

3. Background

3.1 The

Bell Island treatment plant started operating in the early 1980’s.

3.2 Currently

there is only one electrical cable supplying power to Bell Island WWTP.

This cable is owned by Network Tasman and crosses the estuary south of the

plant. It has a capacity of 2.0 MW.

3.3 Having

only one cable is a risk to the ongoing supply of power to the plant.

This risk to supply was initially identified during Engineering Lifelines

studies undertaken around 2007/2008 for the region.

3.4 Prior

to 2010, the NRSBU were considering an upgrade to the treatment plant and this

included the option of dewatering sludge. The NRSBU asked Network Tasman

for options on increasing the power supply to Bell Island to meet the

electrical demands of sludge dewatering.

3.5 Network

Tasman responded with the following statements:

· “The most limiting factor is the size of the existing 11kV

cabling and the amount of current that can travel through the cable before

damage occurs. When the cable is run close to its capacity limit, as it will be

with the proposed capacity increase, the probability of failure increases

rapidly.

· Whilst a fault to a cable upon Bells Island may take a couple of

days to repair or a week to replace, if the cable fault were to occur under the

estuary the repair may take several weeks and the replacement would take

considerably longer.

· Network Tasman Limited strongly recommend that a backup supply is

looked into whether it be generation or a second secure 11kV supply to the

island, either across the causeway or through the estuary (overhead or

underground) as there will be no quick fix if the estuary cable fails.”

· “Your [WWTP] co-incident load, ie when everything peaks at one

time, will be the limitation and naturally as more load comes on the cable

heats up (i^2r) until the insulation finally breaks down. It is therefore

unwise to run the cable beyond full load or our case we prefer not to run

cables etc continually at their FL rating anyway just to give longer

life.”

3.6 This

response from Network Tasman clearly indicated that the cable had

limitations. The NRSBU would need to consider the additional cost of

increasing the supply capacity.

3.7 However,

during the 2010 upgrade it was decided not to progress with the dewatering

component of the upgrade. This additional capacity was therefore not

required and the plant could continue to operate within the capacity of the

current cable. The peak use is currently 1.2 MW compared to the cable

capacity of 2.0 MW.

3.8 The

security of supply associated with a single cable still remains a risk and the

NRSBU have asked Network Tasman to review and respond to this risk.

3.9 Since

2010, the NRSBU has implemented procedures to ensure that electricity demand

remained within the design capacity of the power cable. For instance,

when the discharge pump (Outfall) starts operating, one of the 6 larger

aerators is programmed to switch off to keep the power demand consistent.

4. Network

Tasman Proposal

4.1 After considering the risk

associated with a single cable, Network Tasman has confirmed that as a

supplier, the most cost-effective solution is a second underground cable to the

Bell Island WWTP. This cable would be on a separate alignment to the

current cable and run from the overhead supply on Best Island, along the golf

course fairway adjacent to the treatment plant access road, under the estuary

and along to the treatment plant. Network Tasman has secured easements

along the proposed route.

4.2 The total cost of the project

is estimated at $447,000. This is greater than what Network Tasman had

budgeted for the work and it has requested that NRSBU consider sharing the cost

50:50. This would require NRSBU funding $223,500 (plus GST).

Network Tasman would own the cable.

4.3 Although Network Tasman are

contracted to supply electricity, it has not guaranteed to provide a continuous

supply 100% of the time. This is not unusual as events do occur that can

interrupt supply which are beyond Network Tasman’s control. This

includes the current cable failing.

4.4 The key issue for the NRSBU

is the impact of no power supply for what could potentially be up to a week

should the cable fail.

4.5 Network Tasman has confirmed

that the proposed cable will have around 20% greater capacity than the current

supply cable. Although this is not of benefit to the NRSBU at present, it

could be of benefit if any future upgrade at the plant is required.

4.6 Network Tasman has indicated

that the second cable would be configured in such a way that it would become

immediately operable should the current cable fail.

4.7 The NRSBU considered the

Network Tasman proposal at its meeting 16 September 2016. It requested

that more research on the risks of power failure and the comparative costs of

backup generation to mitigate those risks.

4.8 Rather than focus purely on

the single cable, an assessment has been undertaken focusing on the business

continuity risks associated with various power disruption scenarios. The

following section summarises that assessment.

5. Business

Continuity Assessment – Power Supply Disruption

Operational

Demands

5.1 The current WWTP operational

demands peak at 1.2 MW which is comfortably within the 2.0 MW capacity of the

cable. Consequently, the risks of the current cable failing because of

capacity exceedance is very low, if not negligible.

Power Disruption

Scenarios

5.2 There are four scenarios that

could threaten the continuity of the power to the Bell Island WWTP. These

are summarised in increasing scale as follows:

5.2.1 Scenario 1 - Minor power disruption for

up to 4 hours at any one time – this is likely to be a local failure that

interrupts supply or a more widespread disruption. Network Tasman would

have contingency plans to restore power for this type of disruption.

5.2.2 Scenario 2 - Moderate power disruption

in excess of 4 hours and up to 24 hours – this is likely to be a major

local failure or more widespread disruption that takes longer to

reinstate. Network Tasman would have contingency plans to restore power

for this scenario as well.

5.2.3 Scenario 3 - Significant power

disruption in excess of 24 hours and up to 14 days – this is could be the

failure of the current cable and Network Tasman would need to locate and

identify the fault and restore power. This scenario is likely to be more

widespread post a serious natural event that would probably result in an

emergency declaration and probably comprise repairs to power infrastructure

across the Nelson/Tasman Region. Network Tasman would probably require

additional expertise and resources from other parts of New Zealand to help with

this scenario. The resumption of power services would take time.

5.2.4 Scenario 4 - Major power disruption in

excess of 14 days – this is likely to be a major natural event that has

probably impacted the greater Tasman/Nelson region. Network Tasman would

probably require additional expertise and resources from other parts of New

Zealand and maybe internationally to help with this scenario. The

resumption of power services would take time and the priority would be the

welfare of people and animals. The Bell Island WWTP would have lower

priority.

Scenario Risk

Assessments

5.3 The likelihood of Scenario

1 occurring is almost certain. Currently power failures ranging from

15 minutes to 1 hour occur 2-5 times per year. Although the power is

usually restored the consequence of these types of power failures on the

treatment plant are low. This will be discussed further below

5.4 The likelihood of Scenario

2 occurring could be considered unlikely. They could occur once or

twice over the next 15 – 20 years. Although Network Tasman would

have the capacity and capability to reinstate the power supply in accordance

with its supply contract, the consequence of any power failure to the operation

is considered to be low - medium. This will be discussed further below.

5.5 Scenario 3 includes

the failure of the current cable to the treatment plant. The likelihood

of this occurring is considered to be rare - unlikely. The cable is not

currently stressed and therefore would be expected to last its natural

life. Network Tasman has indicated that it could take up to a week to

locate and identify the fault and restore power. Although Network Tasman

would have the capacity and capability to reinstate the power supply in

accordance with its supply contract, the consequence of this length of power

outage is considered to be medium - high. This will be discussed further

below.

5.6 The last two scenarios (Scenarios

3 and 4) also comprise major natural events where the priority to reinstate

the Bell Island WWTP power supply would probably be secondary to other health

and welfare demands. Potentially any portable power generation capability

in the region would be deployed to meet other health and welfare demands.

This could also impact generation equipment purchased and installed at the WWTP

as this could be requisitioned by Civil Defence to meet other health and

welfare demands. The likelihood of this scenario to the NRSBU is rare,

however the consequences are considered to be medium to high. This will

be discussed further below.

Bell Island WWTP

– Backup Power Generation

5.7 The NRSBU has completed a

Hazard and Operability Study (HAZOP) for the Bell Island WWTP. The study

concluded that the WWTP could continue to treat wastewater for extended periods

of disrupted power supply. Mobile generators, if available, could be

deployed within days of a power outage if required.

5.8 Previous assessments have

identified several options for backup generation;

5.8.1 The NRSBU arrange with Network Tasman to

manage the deployment of emergency generators when required. Network

Tasman would have the expertise to ensure these generators were appropriately

located on site as well as manage the effects of any backload into its power

supply network.

5.8.2 The NRSBU arrange with Network Tasman to

install a single generator (around 1200kVA) located close to the aeration basin

transformer and feed the other transformers from this point using existing

Network Tasman cabling (Network Tasman would have to implement and manage this

option).

5.8.3 The NRSBU arrange with Network Tasman to

install an appropriately sized generator at each transformer site – this

would require up to 5 generators of between 100kVA and 500kVA (Network Tasman

would have to implement and manage this option).

5.8.4 The NRSBU install backup generation at

critical locations to minimise the impact of any power disruption (NRSBU would

implement and manage this option).

5.9 Network Tasman has assessed

all these options and concluded that from its perspective a second cable is the

most cost-effective way of providing greater security of supply.

5.10 Between 31 January 2014 and 27 March

2014 the NRSBU did not use any electricity in the aeration basin and this

resulted in minimal (not noticeable) adverse effects. The power

consumption at that time was less than 4,000kWh per day compared to the normal

daily peak of around 13,000kWh.

5.11 Although this trial was undertaken in

the summer months when the pond efficiency is more effective, it does indicate

that the treatment plant is resilient. It can be operated quite

effectively with lower power use and still maintain good performance for

extended periods of time. There would be lesser resilience in the winter

months maybe 3-4 weeks at a maximum.

Risk Assessment

5.12 The risk of a power outage lasting

greater than 14 days is considered to be very low. If it did occur it is

likely to coincide with a major event across the region. The evidence

suggests that the Bell Island WWTP could operate with minimal back-up power

generation for up to 14 days. The only risks during this period would be

potential increase in odour and the increasing risk of a compromised quality of

effluent discharge.

5.13 The critical components over the short

term are the inlet structure and associated electrical controls. The

discharge pump would be the next priority, although it is only likely to be

needed during periods of high flow. These periods could conceivably occur

during a major power outage event e.g. earthquake, major storm, hurricane etc.

5.14 The other components could be left idle

for 2 to 4 weeks before odour, dormant sludge and compromised discharge become

issues. The raw wastewater would be distributed directly from the inlet

structure to the Facultative Oxidation Ponds (FOP) during this period.

There is sufficient buffer in the FOPs to accommodate the additional wastewater

loading if required.

Backup

Generation Options

5.15 A review of the likely power generation

requirements for varying lengths of power disruption is summarised as follows;

5.15.1 Inlet Structure (inlet screens and primary sludge

pumps) – The inlet structure is the most critical component. It

should, preferably, remain operational during any power disruption. This

outcome suggests that the NRSBU should consider installing permanent backup

generation (100Kva) for the inlet structure with automatic cut over in the

event of any power failure. This will keep the inlet screens and primary

sludge pumps functioning whilst allowing screened effluent to flow (under

gravity) to the rest of the treatment plant. This would keep the inlet

structure functional for any length of power disruption.

5.15.2 Outlet Pump – The outlet pump is normally

only required when the outlet flow is greater than normal, which often

coincides with significant stormwater inflow. This outcome suggests that

backup generation (150Kva) would be required if the power disruption occurred

concurrently with high rainfall. This is considered to be realistic

occurrence therefore for the marginal extra cost the permanent inlet structure

generator be increased in size to operate the outlet pump as well.

5.15.3 ATADS and Biosolids Pump – The Autothermal Thermophilic Aerobic Digestion Tanks (ATADs)

and biosolid pumps could be left dormant for up to two weeks without

power. Thereafter they would need to be restarted. Any longer than

two weeks could result in additional odour problems and the need to remove

solids and clean before recommissioning. The ATADS and biosolids pump

would need up to 350kVA backup generation to operate effectively.

5.15.4 Aeration Basin – The aeration basin could be

left for up to 3 weeks without power if it was operating at the time of the

power outage. Any longer than three weeks could result in additional

odour problems. Should the power disruption occur when the aeration basin

is not operational then odour problems are not likely to be an issue. The

aeration basin would need back up generation of up to 500kVA if required to

remain operational in periods of power outage.

5.15.5 Pond Aerators – The pond aerators provide

additional treatment capacity. During a power outage the ponds would

continue to treat wastewater through natural means. The ponds could

possibly treat the full wastewater load for up to four weeks. After four

weeks the quality of the treated effluent discharged into the estuary could be

compromised and odours could begin to occur. The pond aerators would need

back up generation of up to 100kVA to continue to operate in periods of power

outage.

Cost Estimates

5.16 The

back-up generation capital and operational costs are summarised as follows;

|

|

100 kVA Generator

(Inlet Structure only)

|

250kVA Generator

(Inlet Structure and Discharge Pump)

|

|

Supply and install

|

$46,000

|

$80,000

|

|

Power Synchronising

Controls

|

$6000

|

$6000

|

|

Upgrade

switchboard

|

$40,000

|

$40,000

|

|

Upgrade controls

|

$7,000

|

$7,000

|

|

Harmonic

correction

|

$10,000

|

$10,000

|

|

Total Estimate

|

$109,000

|

$143,000

|

|

Maintenance

|

$3,500/yr

|

$4,500/yr

|

|

Operation

|

$600/day

|

$1,500/day

|

6. Summary

6.1 The WWTP is very resilient in

that the Facultative Oxidation Ponds (FOPs) can operate effectively for short

periods (2-3 weeks) without aeration – potentially longer periods during

summer.

6.2 The WWTP has been configured

to ensure that the power draw-off is well within the capacity of the current

power supply cable. This is important for the long-term durability of the

cable. The cable is therefore less likely to fail. However in the

event of failure Network Tasman has indicated it could take up to a week to

locate the fault and repair it.

6.3 The inlet structure is the

most vulnerable component to power outages. Incoming wastewater needs to be

screened. Minor power outages can occur. The inlet screens stop

operating and the screenings build up and unscreened wastewater enters the

plant. After power outages the inlet screens need to be reset.

Funding the installation of backup generation for the inlet structure would be

appropriate. It would cater for both minor and major power disruptions

i.e. minutes, hours, days or weeks.

6.4 The flow from the inlet

structure can gravity to the rest of the plant and distributed to the FOPs

without further pumping.

6.5 The Aerator Basin and the

ATADs can cease operating for up to 2 weeks without major concern (beyond 2

weeks there could result in increasing odour issues).

7. Conclusion

7.1 The conclusion is that there

is no justification for the NRSBU contributing to the 2nd power cable.

7.2 The NRSBU should consider the

installation of permanent backup generation at the inlet structure. This

can be included in the next revision of the Business Plan.

7.3 The risk of extended periods

of power disruption is sufficiently low. Combining this with the natural

resilience of the WWTP, it is concluded that no further permanent backup

generation is required.

7.4 The business continuity plan

should include contingency plans to respond to the unlikely occurrence of an

extended period of power disruption.

Richard

Kirby

Consulting

Engineer

Attachments

Nil

|

Important considerations for decision making

|

|

1. Fit

with Purpose of Local Government

This project fits in with the purpose of local

government as it contributes to meeting the current and future needs of

communities for good-quality local infrastructure and local public services.

|

|

2. Consistency

with Community Outcomes and Council Policy

This report is in line with the objectives of the

Nelson Regional Sewerage Business Unit in the provision of cost-effective

collection and treatment of wastewater.

|

|

3. Risk

The risks related to power failures are outlined in

the report and the risks associated with the recommended option have been

highlighted and dealt with.

|

|

4. Financial

impact

The recommended option is proposed to be included in

the Draft Business Plan 2017/18 with the intention of funding it in that

year.

|

|

5. Degree

of significance and level of engagement

This matter is of low significance because it

relates to enhancing the business continuity for the wastewater treatment

plant operations.

|

|

6. Inclusion

of Māori in the decision making process

Consultation with Maori will occur as part of the

Draft Annual Plan 2017/18 consultation process.

|

|

7. Delegations

The Joint Committee has the responsibility for

considering the backup power supply as part of management of the Nelson

Regional Sewerage Business Unit and report to Council through its draft

Business Plan 2017/18.

|

|

|

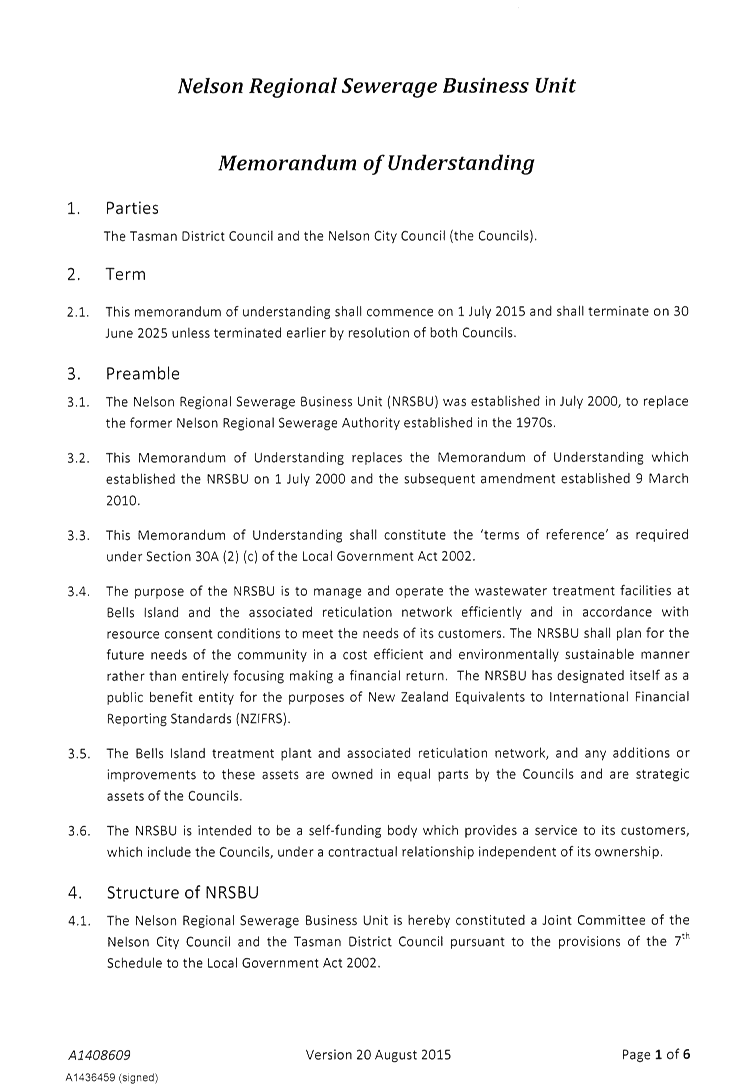

Nelson Regional Sewerage Business Unit

9 December 2016

|

REPORT R6816

General

Manager's Report

1. Purpose

of Report

1.1 To

report on the NRSBU operational activities over the last few months and outline

what is proposed over the next few months.

2. Recommendation

|

That the Business Unit

Receives the General Manager's

Report (R6816) and its

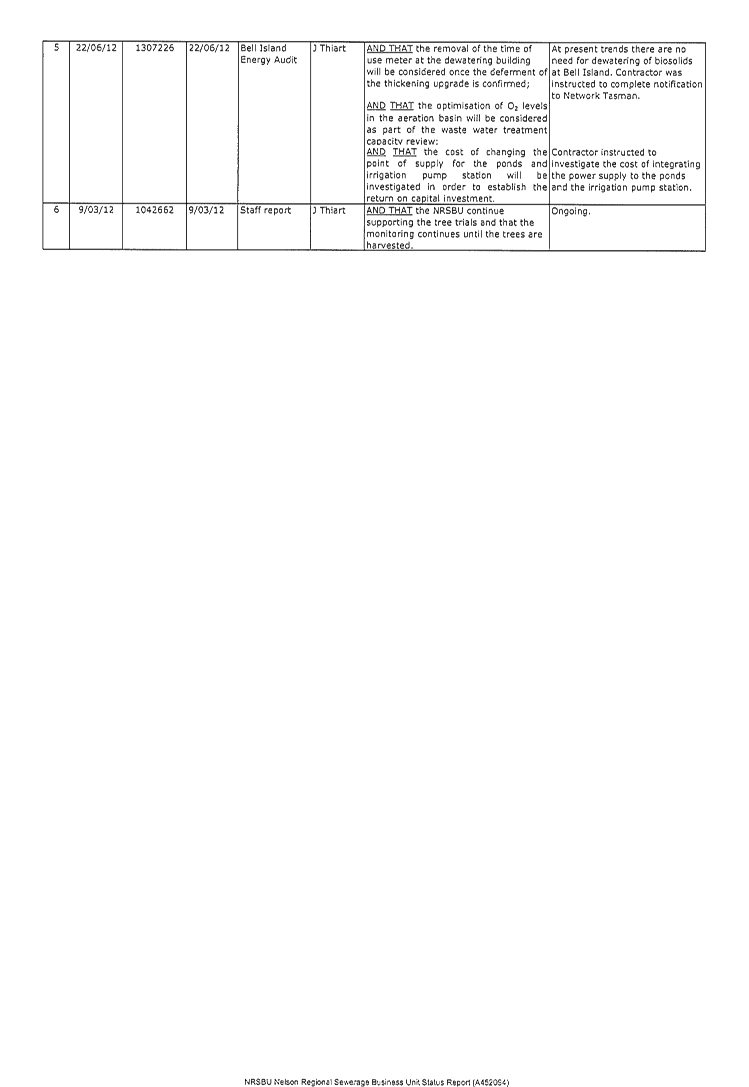

attachments (A1649724, A1665105, A1645078, A1436459, A452094, and A1664757);

and

Approves

the Draft Business Plan 2017/18 (A1664757).

|

3. Bokashi

Logic Proposal

3.1 The

Bokashi Logic was initially presented to the NRSBU in late 2015. The NRSBU held

a workshop on 23 February 2016 to discuss the merits of the proposal as

presented. Essentially Bokashi Logic were suggesting that EM (effective

micro-organisms) when added to the facultative and maturation ponds would

enhance treatment of the sludge. Bokashi proposed trials which would require

investment by the NRSBU.

3.2 The

consensus was that more evidence needed to be produced to substantiate the

claims. Bokashi Logic were asked to revise their proposal requiring more risk

on its part into the outcome of the trials.

3.3 At

its meetings 24 June 2016 and 16 September 2016, the NRSBU was given an update

on progress with this proposal.

3.4 Although

the Bokashi Logic proposal outlined a trial process, it still has not included

any details on a testing regime to demonstrate how the biosolids are affected

by the introduction of the additive. Specific sampling and laboratory

testing would be required to validate the results and it was unclear from the

proposal who would be responsible for this cost.

3.5 In

proposing the trial, Bokashi Logic requested a financial contribution of $9,000

to run the trial over a period of approximately 100 days.

3.6 The

NRSBU requested this additional detail and has received a response from Bokashi

which has outlined a revised trail involving 8 x 1,000 litre water tanks.

The NRSBU has met Bokashi on site and been briefed on the revised proposal.

These trials and the liability of the proposed costs are still being finalised.

3.7 Since

the 16 September 2016 meeting, there has been no further contact from Bokashi

Logic. The NRSBU is not aware of any further progress on this

proposal. Until Bokashi Logic furnish a more details around the proposal

and who will be responsible for the costs and risk, it is proposed that this

not be reported on any further.

4. Accidental

Discharge Consent – Nelson City Council

4.1 The

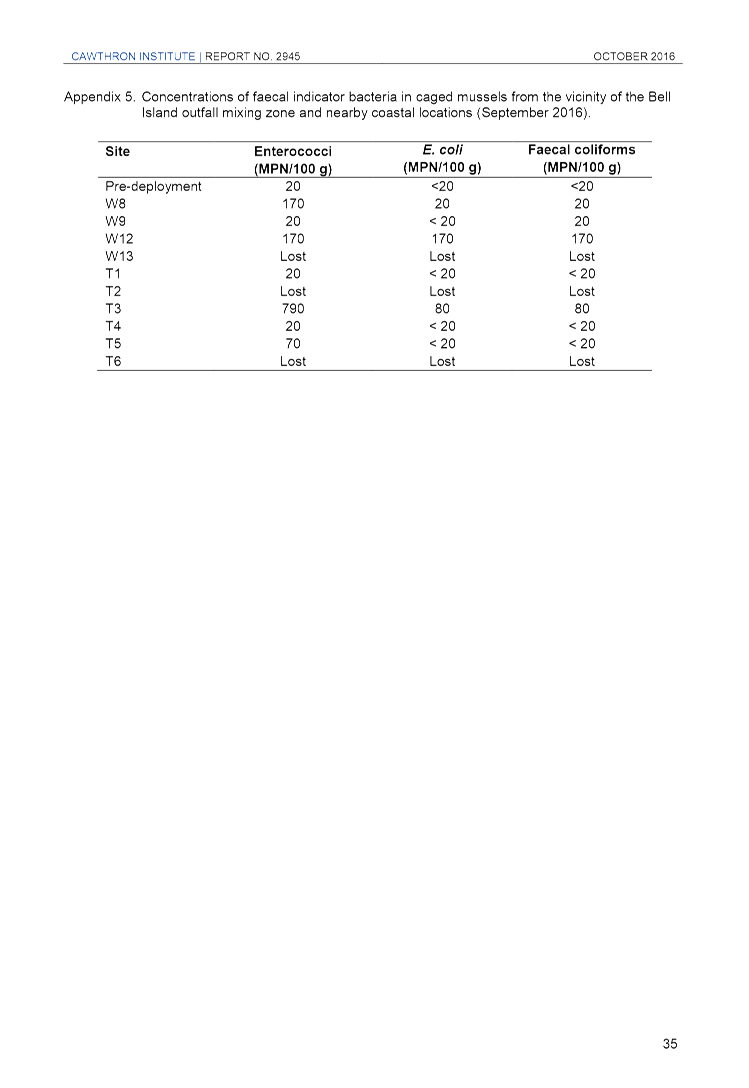

NRSBU lodged an application for a resource consent for the accidental discharge

of wastewater into the estuary. This was primarily from the NRSBU

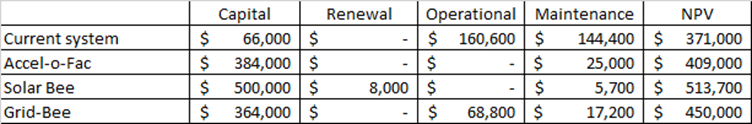

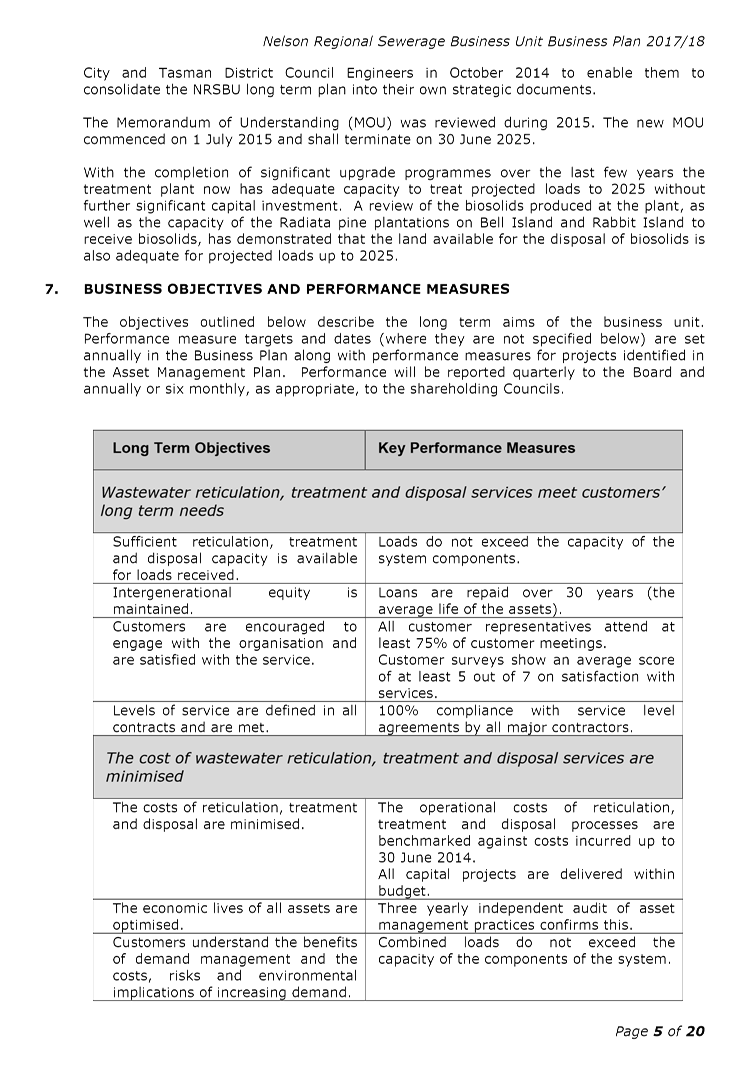

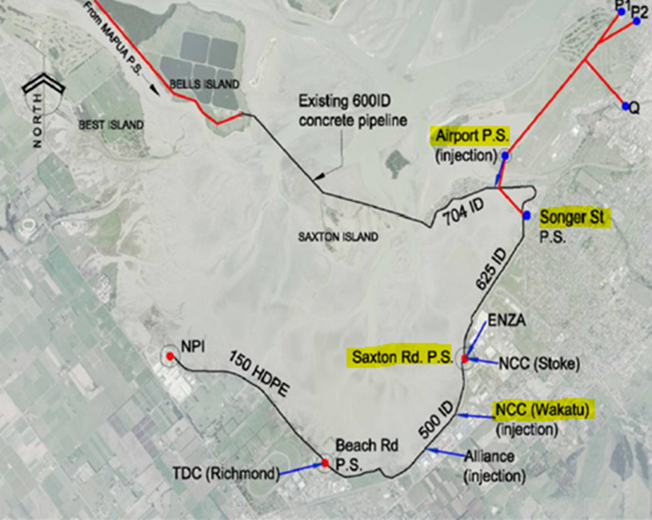

reticulation and pumpstations. The layout of this infrastructure is shown

in Figure 2.0 below.

4.2 This

was initially lodged on 23 July 2015 with the Nelson City Council (consenting

authority). NCC subsequently requested additional information and this was

collated and lodged 29 February 2016.

4.3 The

application was notified publically during August/September 2016 and

submissions closed at the beginning of November 2016.

4.4 Thirty

five submissions were received.

· One submission was

in support of the consent.

· Four of the

submissions did not oppose the consent application and asked to be heard.

· The

other submissions all opposed the application submission mainly on the grounds

that the discharge of any raw sewage to the Waimea Inlet is unacceptable.

Figure 2.0 Showing

NRSBU Reticulation, Connections and Pumpstations

4.5 A

more fundamental issue raised by the submitters is the perceived inactivity by

Nelson City Council and Tasman District Council at addressing storm water

inflow and infiltration. (If Board members wish to review the submissions

received these will be made available on request)

4.6 Following

evaluation of the submissions it was decided to retain the services of Fluent

Solutions (Designers of the regional pipeline upgrade project) to provide

engineering expert witness at the hearing and Cooper Rapley (John Maassen) to

provide legal support for the project.

4.7 The

public hearing for the application is expected to be held in March 2017.

4.8 It

should be noted that the discharge of wastewater in Tasman District Councils is

a prohibited activity and therefore a consent application cannot be submitted.

5. Office

of the Auditor General - Annual Audits Arrangements

5.1 The

Office of the Auditor-General (OAG) has sent a letter setting out the

procedures to renew the contract with the NRSBU for the annual audits of its

accounts. The OAG proposes to engage Audit New Zealand to continue

undertaking these audits on its behalf.

5.2 It

was agreed that a Draft Audit Proposal will be prepared for discussion with the

NRSBU with the objective of renewing the agreement for a further three years.

6. Pump

Station Energy Review

6.1 Enercon

was commissioned to review the operation of NRSBU pump stations with the view

to identify energy saving opportunities. The report confirms that the systems

run efficiently.

6.2 The

report does outline improvements that could be made to the management of the

storm pumps during periods of high flow. The improvements would optimise

pump operations to respond more effectively to flow variations during high flow

events.

6.3 However,

the associated costs and risks of these improvements which include

reprogramming control systems, do not justify changing the pump controls for

what is at best a very marginal cost saving.

6.4 It

is therefore proposed to continue the current practice. The operators monitor

the flows at the pump stations during wet weather events and reset control

systems once the high flows have dropped to the point where they and can be

managed by one storm pump.

7. Impact

of the Bell Island Regional Treated Effluent Discharge on the Coastal

Environment : 5 Yearly report

7.1 This

is a report that the NRSBU commission every 5 years to determine the impact of

the effluent discharge on the coastal environment.

7.2 The

report confirms that continued discharge of treated wastewater from Bell Island

has no discernible impact on the environment. It states that;

· Seawater

stratification characteristics indicate rapid mixing of the low salinity

wastewater discharge with estuarine receiving waters within the ebb tide flow

channels.

· Receiving water

nutrient concentrations indicate adequate dilution down-current from the Bell

Island wastewater outfall to prevent development of eutrophication.

· Ammoniacal-N

concentrations at all sites were well below ANZECC (2000) and USEPA (1986)

guideline trigger levels, ensuring that potentially toxic conditions were not

achieved.

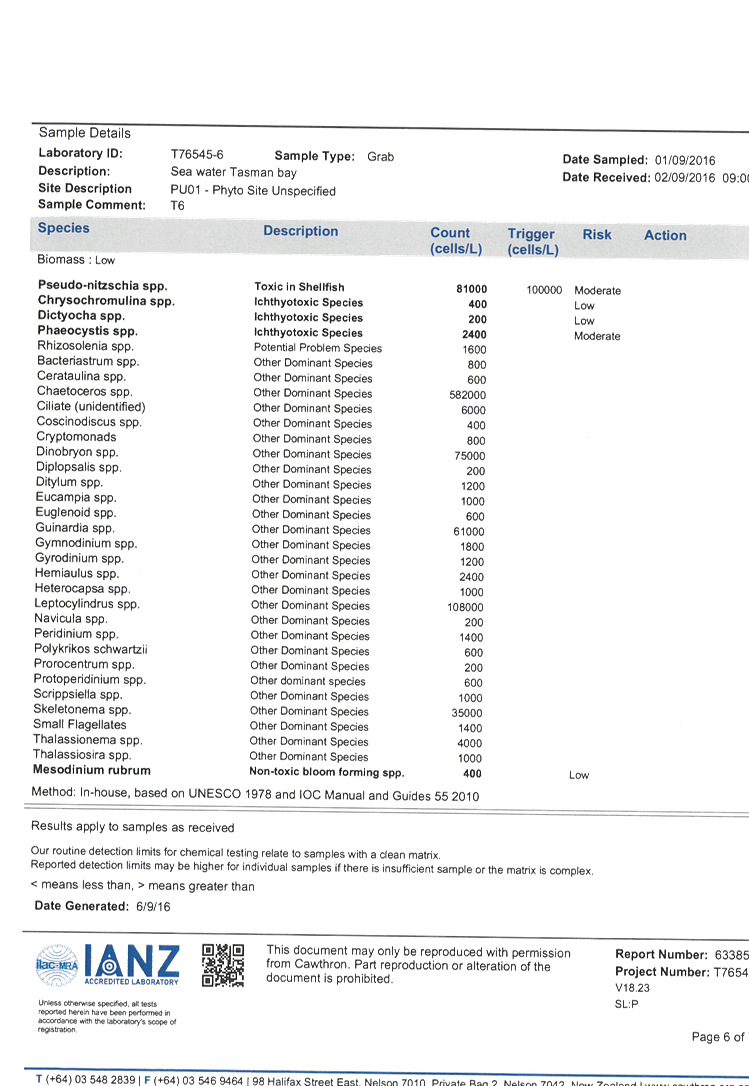

· Phytoplankton

characteristics at inner Tasman Bay sites were considered to be normal for the

region, reflecting the seasonally productive spring diatom growth period but

showing no discharge-related signs of over-enrichment or stimulation of

undesirable species.

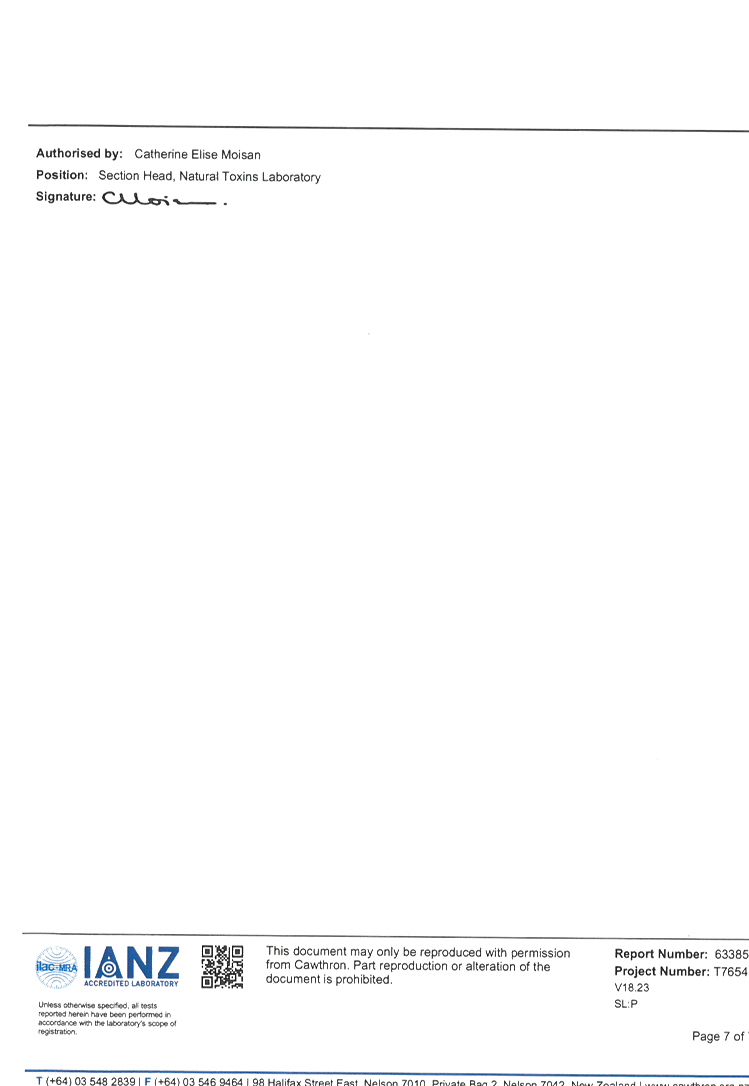

· Receiving water

faecal coliform and enterococci concentrations indicate that the Bell Island

outfall discharge was not a significant source of bacterial contamination

during the sampling period.

· Concentrations of

faecal coliforms and enterococci in mussels, summarised from 16 bio-monitoring

surveys (2008-2016), indicate that contributions from the Bell Island discharge

were minor in comparison to catchment runoff.”

7.3 The report suggests that

additional investigations in the relationships between catchment sources of

contaminants and estuary water quality could be useful. It would assist

in the interpretation of the relative significance of point-source discharges,

such as the Bell Island wastewater discharge. The report implies that

other sources of contaminants have a more significant impact on water quality

in the Waimea Inlet.

8. WWTP

- Discharge Consent Renewal

8.1 The

discharge consent for the Bell Island Wastewater Treatment Plant expires on 7

February 2018. The consent comprises the discharge of treated wastewater to the

Waimea Inlet, the discharge of treated wastewater to land at Bell Island and

the discharges to air related to the wastewater treatment plant at Bell Island.

8.2 Significant data sets are now

available on the performance of the treatment plant in terms of the effects of

discharges from Bell Island. Analyses of the performance of the treatment plant

suggest that the improvements have facilitated compliance with the objectives

of the consent.

8.3 The

NRSBU is engaging appropriate expertise to develop the application.

Request for Proposals for the professional services and legal services

closed on 1 December 2016. They are currently being assessed using the Brookes

Law methodology.

8.4 It is anticipated that both

professional services and legal services will commence working on the consent

application from 16 January 2017.

8.5 The project will need to be managed actively to

consolidate the consent application for lodgement with the consent authority in

early August 2017.

9. Pond

Sludge Management

9.1 At

its meeting 24th June, the NRSBU were briefed on a proposal from

Gurney Environmental regarding the installation of Accel-o-Fac aerators in the

ponds to reduce sludge production and volumes. The intention was to

undertake more research to achieve more certainty around the cost-effectiveness

of this proposal and associated investment.

9.2 The

NRSBU has progressed the investigations including a meeting with a wastewater

specialist at Massey University who has seen the equipment in the UK. The

NRSBU obtained some feedback and suggested a course of action for further

investigations.

9.3 The

results of the assessment and conclusions are outlined in a separate report on

this agenda.

10. Contract

3458 – Operation and Maintenance

10.1 The reticulation and treatment

operations have continued as normal over the last few months. The

effluent discharge continues to meet consent conditions and sludge produced at

the treatment plant complies with Class A biosolids quality.

10.2 The ponds continue to perform

well. Loads are diverted away from the activated sludge area and into the

ponds to utilise the capacity of the ponds during the summer months resulting

in energy savings in the aeration basin.

10.3 Following the recent blockage on the

biosolids transfer pipeline, trials of different types of pigs on different

types sludge transfer pipelines have been undertaken. These trials

indicated that sludge build up can be better managed through better selection

of pigs and changing pump controls. The result is that pigging is carried

out under increased flow velocity.

10.4 The operational costs are tracking ahead

of budget. These are primarily due to the costs associated with clearing

the blockages in the biosolids and primary sludge transfer pipelines. The

operations of the plant are being optimised to better utilise the capacity in

the ponds, thereby reducing costs. It is intended that savings will be

made over the remaining part of the year to cover the additional costs to date.

10.5 The

use of the belt thickener to manage the thickening of primary sludge has

resulted in a significant increase of cost. The methodology used by the

contractor to thicken up the primary sludge is currently under review as the

expected decrease in biosolids produced has not reduced as anticipated.

With ENZA going off line until March 2017 it is not expected that any further

thickening of primary sludge will be required until then.

10.6 The

aeration basin and secondary clarifier will be taken off line during December

2016 for annual maintenance and additional condition assessment of the

secondary clarifier mechanical components.

Songer Street Pump Station: Blockages

10.7 There

have been recent blockages occurring in the Songer Street Pumpstation.

These have been caused by increased stormwater infiltration flows picking up

settled solids and items in the reticulation and flushing them into the

pumpstation all at once.

10.8 The

control systems have been modified and appear to have mitigated the problems

experienced. NCC officers continue work on managing the problems in the

reticulation upstream of the pump station.

11. Contract

3619 – Biosolids Operation

11.1 The

monthly average volume of biosolids sprayed over the last few months have

stayed at higher levels. However they have dropped significantly over the

last month.

11.2 The

projected volume of biosolids that will be sprayed this year are trending to

exceed the volume budgeted for.

12. Key

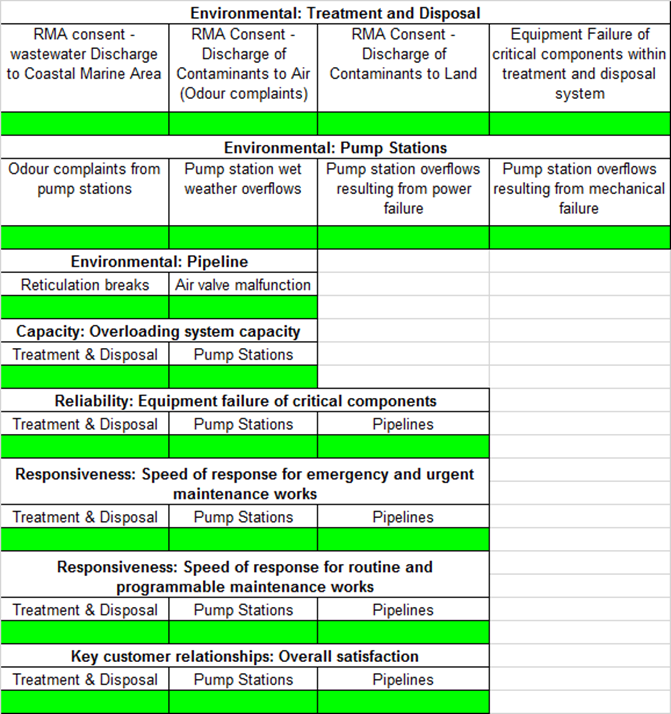

Performance Indicators

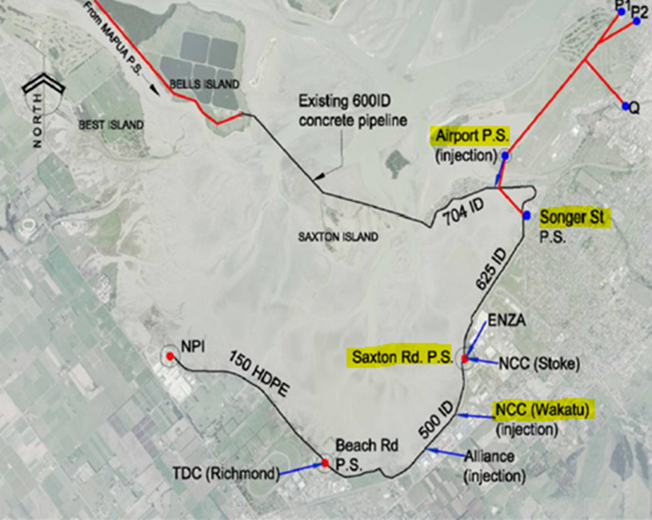

12.1 The

outcomes of key performance indicators for the 3 month period to 31 October

2016.

13. Compliance

Outcomes

13.1 The compliance outcomes for the 12 months to 31 October

2016 are outlined in the following table:

|

i)

|

Resource

Consent Compliance (rolling 12 month record)

|

|

|

Ø Discharge to Estuary Permit

|

Achieved.

|

|

|

Ø Accidental discharges (Consent for

accidental discharges within Nelson City Council area is being sought at

present)

|

Overflows

occurred at the Beach Road, Saxton Road and Songer Street pump station during

the heavy rain event on 24 March 2016. The rainfall event is the second

highest rainfall recorded over a 24 hour period recorded for Nelson since

January 2000.

An overflow

occurred at the Songer Street during wet weather conditions when both storm

pumps blocked on 22 June 2016.

Biosolids

overflow to land and the Waimea estuary following a blow out on biosolids

transfer pipeline on 19 and 20 July 2016.

|

|

|

Ø Discharge to Air Permit

|

100%

Compliance

|

|

|

Ø Biosolids Disposal

|

100%

Compliance

|

|

|

Ø Discharge treated

waste

water to land

|

100% Compliance

|

|

ii)

|

Odour Notifications

|

|

|

Ø Past three months

|

Nil.

|

|

|

Ø Last 12 months

|

Nil.

|

|

iii)

|

Overflows

|

|

|

Ø Past three months

|

Nil.

|

|

|

Ø Last 12 months

|

Five.

|

|

iv)

|

Speed of

response for maintenance works

|

|

|

In past

three months:

Ø Six call outs were associated with

treatment plant issues.

· Aeration basin aerator – 1 event.

· Gravity belt thickener – 2 events.

· Washwater – 1 event.

· Milliscreen – 2 events.

Ø One call out recorded for pump stations.

· Richmond – power failure.

|

|

|

Ø Response within 30 minutes.

Achieved.

|

|

|

|

|

|

14. Review

of Action Plan Implementation –

2014 Asset Management Plan and 2015/16 Business Plan

The following table indicates the draft time lines for

the individual action items:

|

IP

|

Business Plan Action

|

Target Date

|

Completion Date

|

Comments

|

|

1

|

Review

manuals annually.

|

Dec

2016

|

|

Delayed.

Contract manuals are reviewed annually by the contractor and submitted to the

NRSBU for review. All the manuals have been reviewed with the exception of

the Operation and Maintenance Manual. It is expected that this will be comleted

in December 2016.

|

|

2

|

Consolidate

all natural disaster information and review 3 yearly.

|

Mar

2018

|

|

Work

will be carried out as part of next asset management review.

|

|

3

|

Internal

benchmarking carried out annually.

|

Jun

2016

|

Aug

2016

|

Carried

out as part of annual report.

|

|

4

|

Review

risk of contributors leaving NRSBU.

|

Jun

2016

|

Dec

2015

|

Completed.

|

|

5

|

Review

capacity of treatment components.

|

Mar

2017

|

|

Expect

treatment plant model to be in place in March 2017. This will follow an

assessment of S::can results.

|

|

6

|

Programme

for pipe inspections.

|

Dec

2016

|

|

Included

in annual review of Operation and Maintenance Plan.

|

|

7

|

Annual

review of contractor performance.

|

Dec

2016

|

Jun

2016

|

Completed.

|

|

8

|

Screen

upgrade.

|

April

2017

|

|

Variation

issued to Nelmac to proejct manage the installation of the second inlet

screen.

|

|

9

|

Review

secondary sludge separation.

|

May

2017

|

|

Depends

on completion of treatment plant model.

|

|

10

|

Construction

second sludge storage tank.

|

Jun

2017

|

|

Delayed

from June 2016.

|

|

11

|

Develop

sludge removal programme.

|

Jun

2017

|

|

Subject

of a separate report to 9 December 2016 NRSBU Meeting.

|

|

12

|

Review

effluent discharge management.

|

Mar

2016

|

Jan

2016

|

Competed.

|

|

13

|

Renewal

of effluent discharge permit

|

Aug

2018

|

|

Preparation

of application commences in January2017.

|

|

AP

|

AMP

Action

|

Target

Date

|

Completion

Date

|

Comments

|

|

1

|

Annual

customer survey.

|

Mar

2016

|

Apr

2016

|

Completed.

|

|

2

|

Business

Continuity Plan review.

|

Jun

2016

|

Jun

2016

|

Completed.

|

|

3

|

Consider

benefits of succession planning and how it might be implemented once

governance issues (TDC and NCC) have been resolved.

|

Jun

2016

|

June

2016

|

Completed.

|

|

4

|

Review

of security required at all facilities.

|

Mar

2016

|

May

2016

|

Completed.

|

|

5

|

Monitor

sludge levels in ponds and ascertain long term removal and disposal

requirements.

|

Mar

2016

|

Feb

2006

|

Completed.

|

|

6

|

Improve

reporting requirements for asset condition, performance and maintenance from

maintenance contractor.

|

Mar

2016

|

Apr

2016

|

Completed.

|

|

7

|

Implementation

of internal bench marking (using historical data) of NRSBU network, pump

stations, treatment and disposal facilities.

|

Jun

2016

|

|

Delayed

until 2017.

|

|

8

|

Develop

Demand Management Policy.

|

Jun

2016

|

Jun

2016

|

Completed.

|

15. Health

and Safety

15.1 There have been 8 inductions and 207 visitors to the

Bell Island WWTP over the past three months.

15.2 Five health and Safety incidents were reported.

· In two instances operators suffered minor cuts when

attending to mechanical equipment.

· An operator got sprayed with algae when operating the

algae transfer pump. The algae transfer system was inspected and fittings

replaced where required.

· An operator observed unsafe practices employed by

engineering staff. Following an investigation additional site signage was

deployed and information added to isolation permits.

· The team leader observed an incident where a trailer

was towed using an incorrectly sized vehicle. Following an investigation plates

showing the capacity of the trailers were fitted to trailers.

16. Financial

Status

16.1 Expenditure is tracking above budget. This has been a

result of dealing with the biosolids transfer pipeline blockages and the blow

out which was not budgeted for.

16.2 There

has also been an increase in monitoring costs:

· The testing daily

trade waste samples collected from the three industrial contributors, as

arranged following the review of the Agreement for Disposal of Trade

Waste. This amounts to $3,000 per month.

· The cost of the

five yearly environmental monitoring associated with the treated wastewater

discharge. This cost was budgeted for in year 2017/18 instead of 2016/17.

16.3 The

cost of biosolids spraying is expected to exceed the budget for this financial

year as the decrease in biosolids volume following the introduction of sludge

thickening has not eventuated as anticipated. The cost of thickening primary

sludge is projected to exceed the budget by $30,000 for the year.

16.4 The

cost of power supply is tracking well below budget and the annual cost is

expected to be well under budget.

16.5 Current

projections show that operation and maintenance expenditure will exceed the

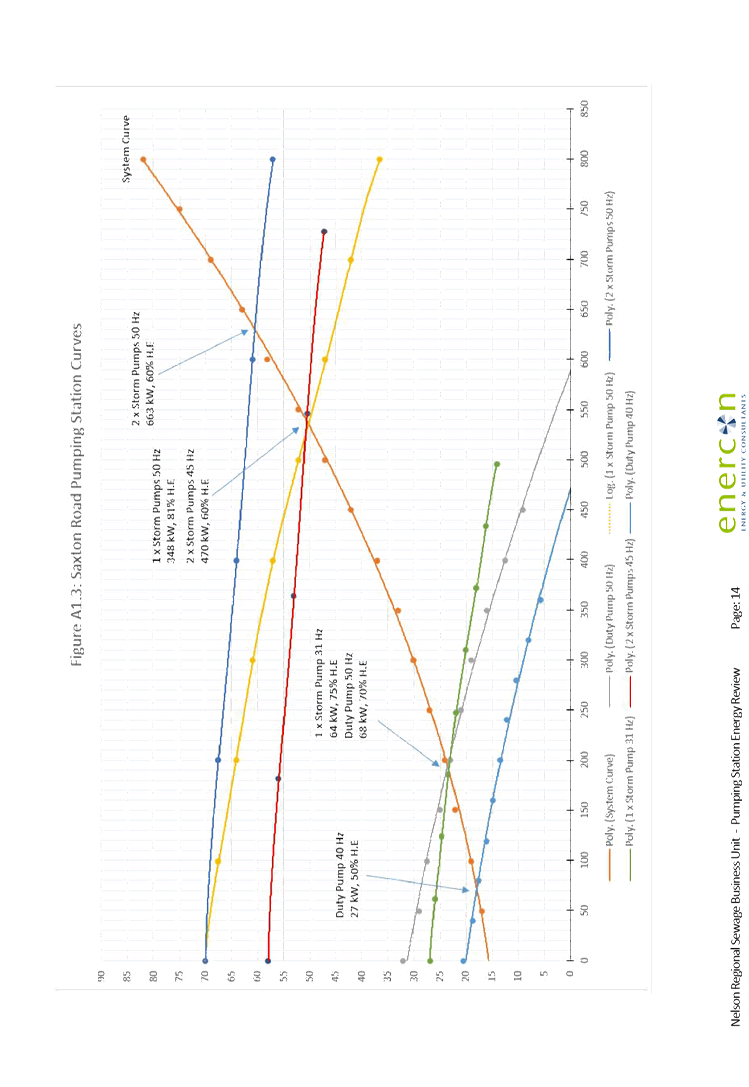

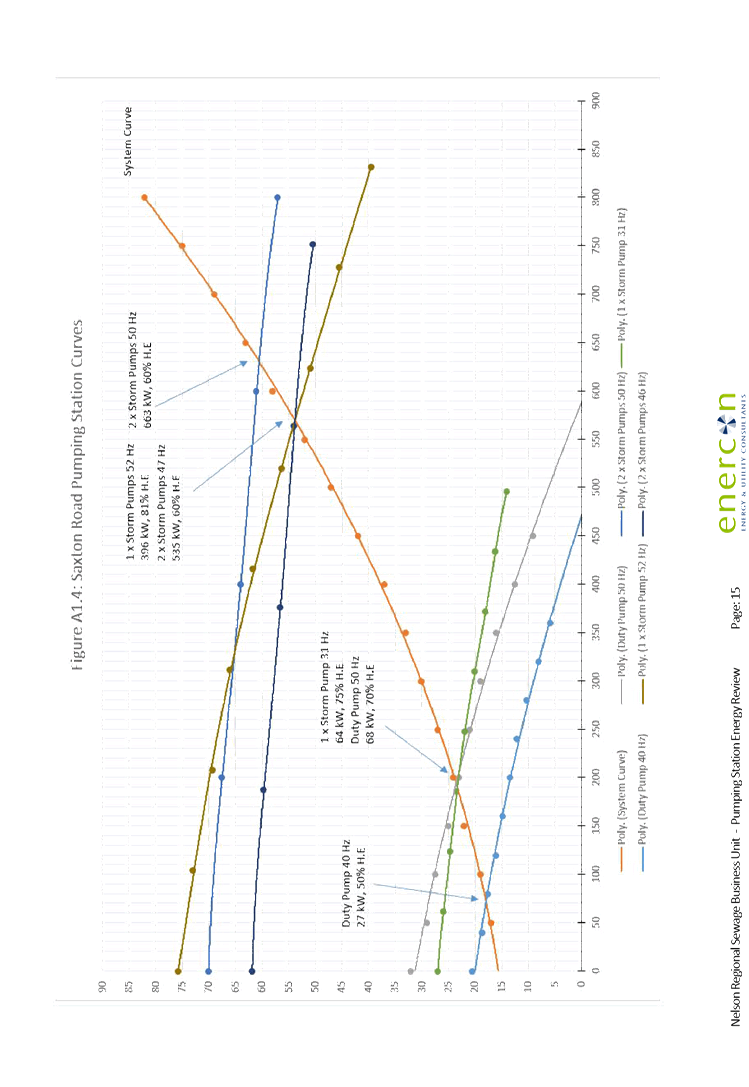

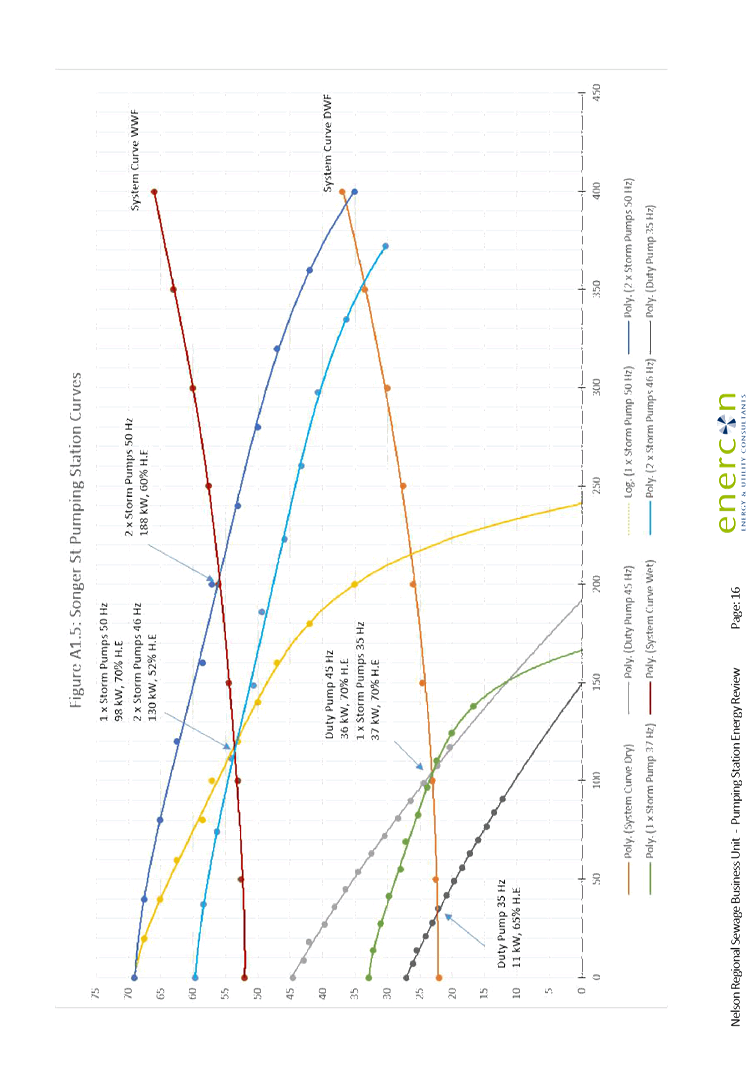

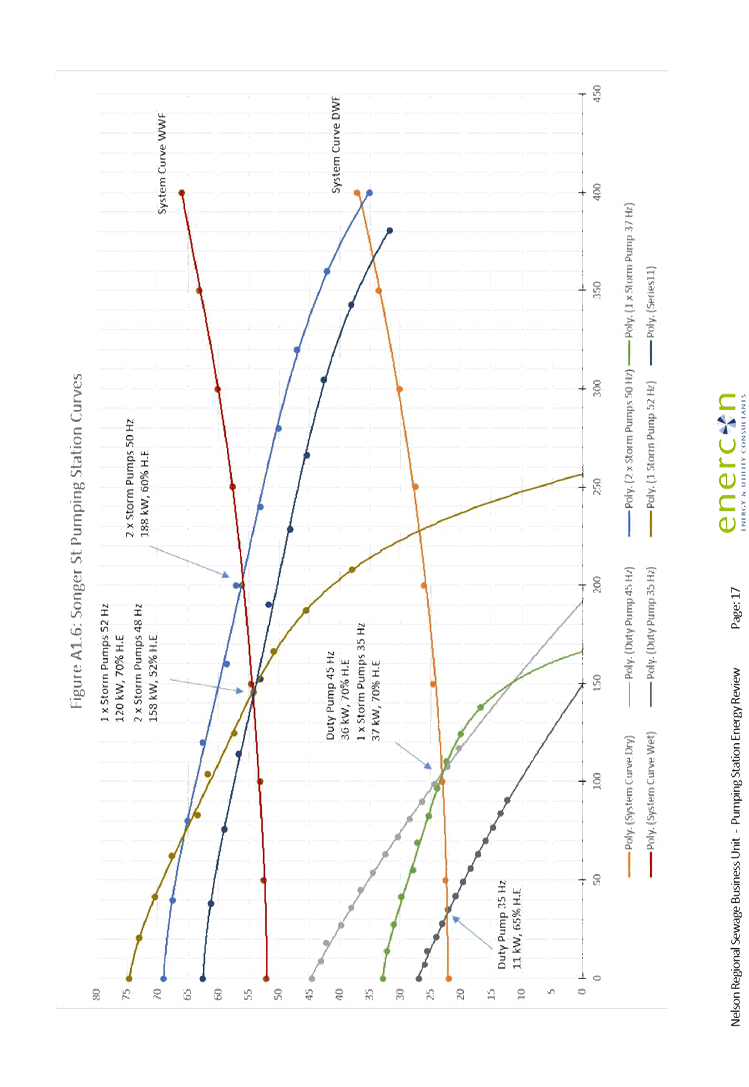

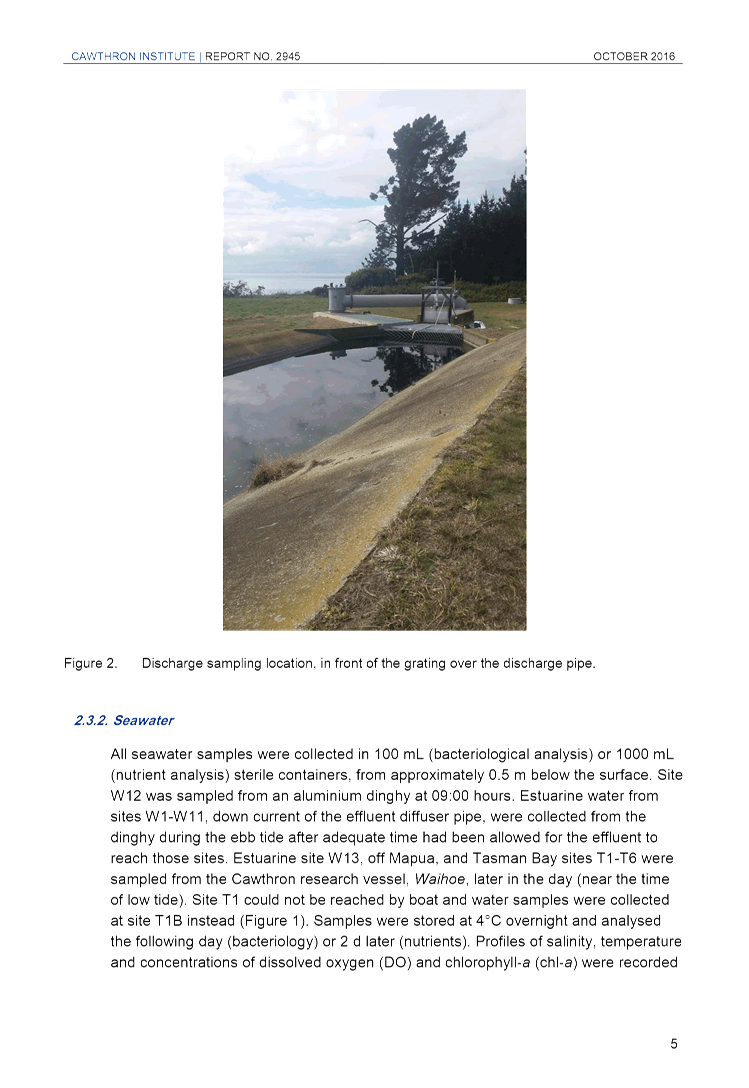

budget by over $100,000. To compensate for this increased expenditure,