AGENDA

Ordinary meeting of the

Nelson Regional Sewerage Business Unit

Friday 11 December 2015

Commencing at 1.00pm

Ruma Mārama

Level 2A, Civic House

110 Trafalgar Street, Nelson

Membership: Nelson City Councillor Ruth Copeland, Mr Derek

Shaw, Tasman District Councillors Barry Dowler and Michael Higgins

Representatives: M Hippolite (Iwi Representative) and P

Wilson (Industry Customers Representative)

Guidelines for councillors

attending the meeting, who are not members of the Committee, as set out in

Standing Orders:

·

All councillors, whether or not they are members of the

Committee, may attend Committee meetings (SO 2.12.2)

·

At the discretion of the Chair, councillors who are not Committee

members may speak, or ask questions about a matter.

·

Only Committee members may vote on any matter before the

Committee (SO 3.14.1)

It is good practice for both Committee members and

non-Committee members to declare any interests in items on the agenda.

They should withdraw from the room for discussion and voting on any of these

items.

Nelson Regional Sewerage Business Unit

11

December 2015

Page

No.

Apologies

1. Confirmation

of Order of Business

2. Interests

2.1 Updates

to the Interests Register

2.2 Identify

any conflicts of interest in the agenda

3. Confirmation

of Minutes

3.1 18

September 2015 5 - 8

Document number M1481

Recommendation

THAT the minutes of the meeting of the Nelson Regional

Sewerage Business Unit, held on 18 September 2015, be confirmed as a true and

correct record.

4. General

Manager's Report 9 - 35

Document number R5189

Recommendation

THAT the report General Manager's

Report (R5189) and its

attachments Draft Business Plan 2016/17 (A1468715) and Status Report (A452094) be received;

AND THAT

the Nelson Regional Sewerage Business Unit not implement the trial proposed by Bokashi

Logic.

5. NRSBU

Review of Alternative Biosolids Disposal Options 36 - 39

Document number R5197

Recommendation

THAT the report NRSBU Review of

Alternative Biosolids Disposal Options (R5197) and its attachment (A1468738) be received;

AND THAT

the current biosolids disposal practice at Bell Island is

economical.

6. NRSBU

Risk Profile - Impacts of Contributor Exit 40 - 42

Document number R5204

Recommendation

THAT the report NRSBU Risk Profile

- Impacts of Contributor Exit (R5204)

be received.

7. NRSBU

Bells Island Wastewater Treatment Plant; Review of Automated Process Control

and Influent Load Monitoring 43 - 46

Document number R5208

Recommendation

THAT the report NRSBU Bells Island

Wastewater Treatment Plant; Review of Automated Process Control and Influent

Load Monitoring (R5208) be

received;

AND THAT

an S::can unit be procured from DCM Process Control and

installed at a cost not exceeding $95,000.

8. Audited

Financial Statements 47 - 65

Document number R5237

Minutes of a meeting of

the Nelson Regional Sewerage Business Unit

Held in Ruma Mārama,

Level 2A, Civic House, 110 Trafalgar Street, Nelson

On Friday 18 September

2015, commencing at 1.01pm

Present: Councillor

M Higgins (Tasman District Council), Councillor R Copeland (Nelson City

Council), and Mr D Shaw

In Attendance: M

Hippolite (Iwi Representative), C McIntyre (Industry Customers’

Representative), Nelson Regional Sewerage Business Unit General Manager (R

Kirby), Senior Asset Engineer – Solid Waste (J Thiart), Management

Accountant (A Bishop), and Administration Adviser (G Brown)

Apology: Councillor

D Dowler (Tasman District Council)

|

1. Appointment of

Chairperson

|

|

|

There was a discussion

regarding appointing a Deputy Chairperson and having alternate councillors

appointed by Tasman District Council and Nelson City Council should a

councillor be unable to attend.

It was agreed that this would

be considered at the start of the new triennium 2016-2019.

|

|

|

Resolved NRSBU/2015/008

THAT

Councillor Higgins be appointed Chairperson of the Nelson Regional Sewerage

Business Unit for the 2013-2016 triennium.

Copeland/Shaw Carried

|

2. Apology

|

Resolved NRSBU/2015/009

THAT an apology be

received and accepted from Councillor Dowler.

Copeland/Shaw Carried

|

3. Confirmation

of Order of Business

There was no change to the order of business.

4. Interests

There were no updates to the

Interests Register, and no other interests with items on the agenda were

declared.

It was requested that the Nelson

Regional Sewerage Business Unit (NRSBU) Interests Register be sent out to

members for review.

5. Memorandum

of Understanding

In response to a question, NRSBU

General Manager, Richard Kirby, advised that the majority of the changes to the

Memorandum of Understanding were minor. He highlighted that the main change was

quorum was now two which consisted of one representative from each Council.

6. Confirmation

of Minutes

6.1 19 June 2015

Document number M1293, agenda

pages 11 - 15 refer.

The following changes were

requested to the minutes:

- Page

12, change ‘trail and peals’ to ‘trials and peaks’

- Page

14, change ‘Instrument’ to ‘Instrumentation’.

|

Resolved NRSBU/2015/010

THAT the amended

minutes of the meeting of the Nelson Regional Sewerage Business Unit, held

on 19 June 2015, be confirmed as a true and correct record.

Shaw/Copeland Carried

|

7. General

Manager's Report

Document number R4817, agenda

pages 16 - 56 refer.

NRSBU General Manager, Richard

Kirby, presented the report.

Mr Kirby advised that Alliance

and Nelson Pine Industries (NPI) had queried readings which the trade waste

charges were based on. He added that Mr Wilson had also raised questions

relating to the difference between the final wash up calculation and the

estimate provided earlier in the year.

It was discussed that the current

charging formula transferred risk for the variable charges to the other main

customers if any customer changed their operations. It was suggested that a

commercial charging structure going forward could be considered. If this was

considered then a review was required as to how this would affect the business

unit.

There was a discussion that if

any if the three industries pulled out, the cost of operating the sewerage

plant would be significantly less as there may not be the need for the ATADs as

urban waste would be handled differently and was a lower cost operation.

It was highlighted the NPI wash

up invoice was $40,000 more than previously estimated even though NPI had

invested in pre-treatment works.

Invoice calculations were

discussed and it was advised that there were no major errors, only a minor

error in relation to the allocation of costs. The main reason for the

difference was the BOD and Suspended Solids treated for NPI in the last three

months were higher than estimated and increased treatment costs as a percentage

of total Operating and maintenance expenditure.

Mr Kirby advised he was meeting

with industry next week and would discuss a costing formula with them. In

response to a question, Mr Kirby said that a charging formula review could be

conducted but that the formula was quite logical. He added that risks needed to

be identified and then the formula modified.

It was discussed that changes

would need to be conducted with industry agreement as it was a legal contract

and industry could withdraw with six months notice.

In response to a question about

whether processes were robust enough, Mr McIntyre commented on the variation in

sampling results and that the sampling largely reflected his firms sampling. Mr

Kirby advised that there was the opportunity to contract an independent person

to audit Nelmac’s sampling to confirm processes were being followed.

It was suggested that a digital

photograph of each sample would be beneficial.

In response to a question, Senior

Asset Engineer – Solid Waste, Johan Thiart, advised that with regards to

the odour concerns at Best Island it seemed to be an operational issue with

fluid found in the basin and too much acid being added.

In response to a further

question, Mr Thiart said geobags would still be used for dewatering but

he was reluctant to use them for biosolids but this was still under review. It

was suggested that odour could be discharged underground using a treating bag

with a canopy.

Mr Kirby highlighted that at the

top of page 20 of the agenda the words ‘with be considered’ needed

to be removed.

Mr Kirby also pointed out that

the ‘Review of security required at all facilities’ should have a

target date of March 2016.

The following changes were

requested to the Annual Report 2014/2015:

- Page

27, the Pump Station Overflows graph is missing one overflow from the 2014/15

statistics

- Suggestion

to add that there were no extreme weather events

- Page

29, Bell Island 2014/15 not 2013/14

- Page

30, 5.3 right hand column, change ‘will be’ to ‘were’

and ‘considerde’ to ‘considered’

- Page

31, 5.6 note all communication with residents

- Page

33, check ‘Biological Oxygen Demand kg/day’ graph statistics

- Page

36, remove comment

|

Resolved NRSBU/2015/011

THAT the report General

Manager's Report (R4817) and

its attachments (A1422904, A1423020) be

received;

AND

THAT the amended Annual Report 2015/16 be adopted subject

to any audit amendments.

Copeland/Higgins Carried

|

Attendance: Councillor Copeland left

the meeting at 2.36pm.

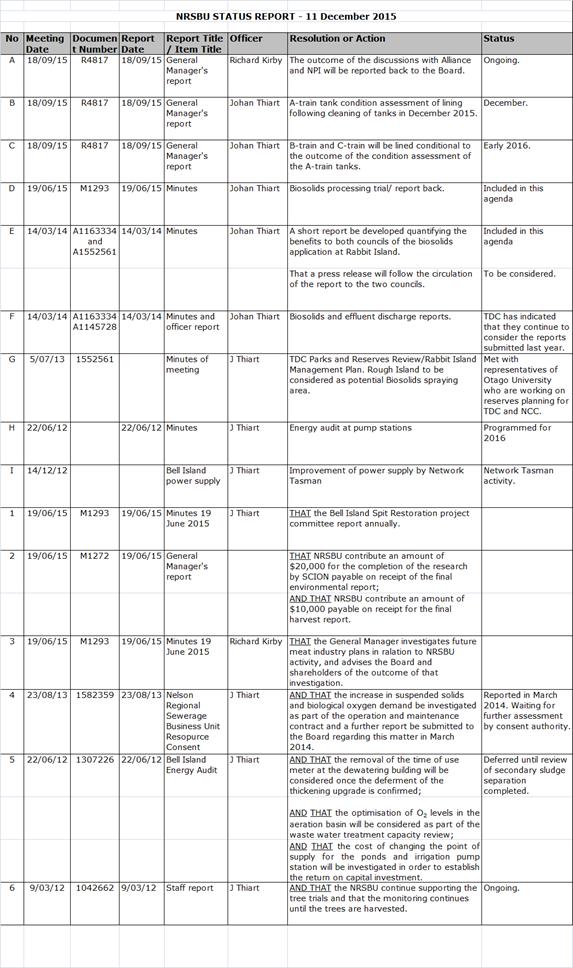

Mr Kirby discussed the status

report items.

There being no further business the

meeting ended at 2.41pm.

Confirmed as a correct record of proceedings:

Chairperson

Date

Chairperson

Date

|

|

Nelson Regional Sewerage Business Unit

11 December 2015

|

REPORT R5189

General

Manager's Report

1. Purpose of Report

1.1 To

report on progress with the NRSBU operational activities over the last

few months and outlining what is proposed over the next few months.

2. Recommendation

|

THAT the report General

Manager's Report (R5189) and

its attachments Draft Business Plan 2016/17 (A1468715) and Status Report

(A452094) be received;

AND THAT

the Nelson Regional Sewerage Business Unit not implement the trial proposed

by Bokashi Logic.

|

3. Correspondence Received

Proposed Environmental Solution for Wastewater

Treatment

3.1 The

NRSBU has received an offer from a company called Bokashi Logic to undertake a

trial using effective micro-organism (EM) technology to improve treatment

efficiency at the NRSBU Bells Island wastewater treatment plant.

3.2 Bokashi

Logic has offered to run this trial at a cost of $54,570 to the NRSBU.

The company wants to demonstrate the efficacy of improving the sludge treatment

capacity of the facultative ponds through the application of an additive (EM

technology) to the ponds.

3.3 The

trial requires the isolation of one of the three facultative ponds at Bell

Island for a period of six months.

3.4 Should

the trial prove effective then it is estimated that the on-going annual cost to

the NRSBU would be around $200,000. This has been calculated based on

information received from Bokashi Logic.

3.5 The

saving that this EM Technology could accrue in operational costs is likely to

be around $110,000 per annum. This has been determined based on the

annualised net present value of desludging the ponds every twenty years at a

5.5% discount interest rate.

3.6 Scientific

research has shown that healthy facultative ponds are supported by

micro-organisms more varied and prolific than what can be added using this

technology. It becomes apparent from research that the additive will have a

positive effect on biologic systems where there is a deficiency in

micro-organisms.

3.7 This

technology was used at Bell Island in the past to try and overcome odour issues

with no demonstrable improvements.

3.8 Based on the information received, it is considered

that there is no cost-effective advantage in implementing the trial.

Greenacres Golf Club

3.9 A

letter was received from the Greenacres Golf Club notifying the Board that they

are interested in using wastewater treated from Bell Island in future.

3.10 The Golf Club was

informed that there is no intention to reticulate water from Bell Island in the

current Business Plan and that the Board could investigate the viability of

reticulating recycled water and consider this for inclusion into the

Council’s 2018-28 Long- term Plans.

4. Recent Actions

Accidental Discharge Consent Application

4.1 The

application was lodged and returned on 23 July 2015 as it was considered to be

incomplete. Additional work has been compiled and put into the amended

application. The amended application will be ready for review in December

2015.

4.2 Once

the amended application is received by the NRSBU it will be reviewed by a

lawyer specialising in Resource Management activities. (A proposal from Duncan

Cotterill to review the application to the value of $2,000 plus disbursements

has been accepted).

4.3 When

the review has been completed the application will be lodged again.

Contract 3458 – Nelmac; Operation and

Maintenance

4.4 The

reticulation and treatment operations have continued as normal over the last

few months.

4.5 Load

has been diverted away from the aeration basin for the last three weeks to

optimise the use of treatment capacity of the plant. This is expected to

generate power savings and a decrease in biosolids production. It is expected

that this process change is likely to be maintained through to April 2016.

4.6 New

duty pumps have been installed at Airport and Saxton respectively during

November 2015. Duty pumps at Saxton, Airport (one of 2) and Beach Road are now

all fitted with N type impellors and it is anticipated that this will improve

efficiency at all three these pump stations.

Contract 3619 – Biosolids Operation

4.7 The

monthly average volume of biosolids sprayed is tracking the budgeted amount.

4.8 With

changes to the loading of the plant process units, as explained above, it is

expected that the volume of biosolids produced will decrease.

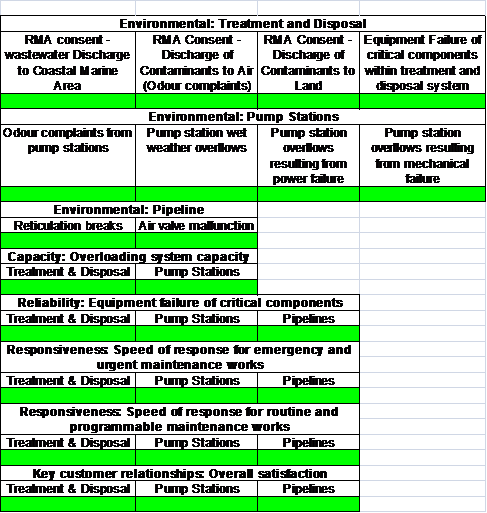

5. Key

Performance Indicators

5.1 The

outcomes of key performance indicators for the 3 months to

31 October 2015 are outlined as follows:

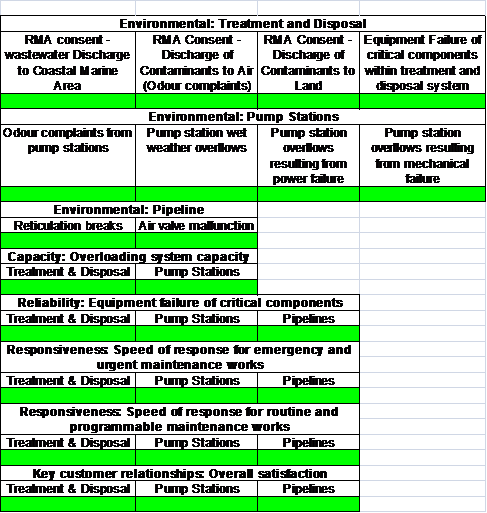

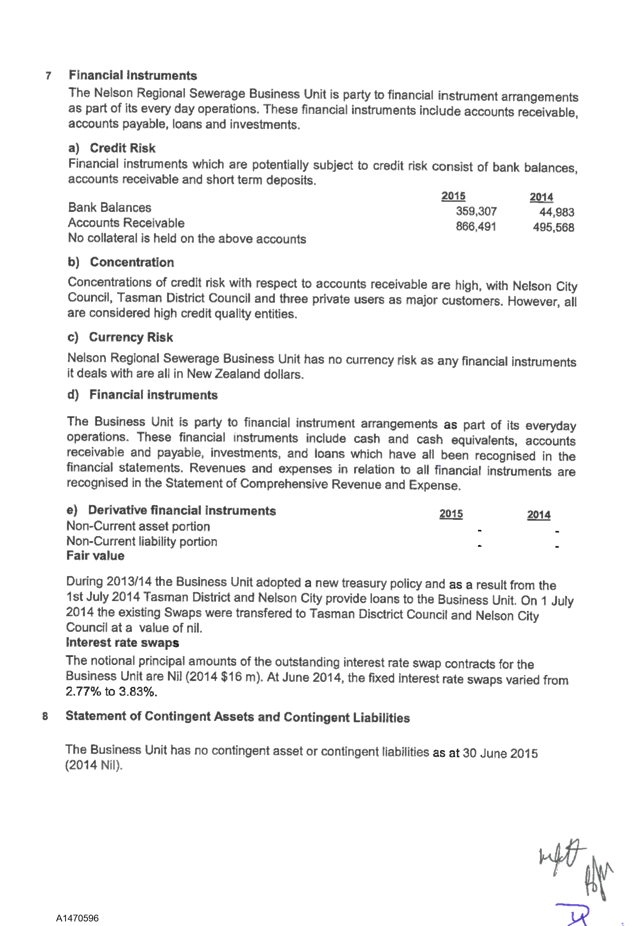

5.2

6. Compliance

Outcomes

6.1 The compliance

outcomes for the 12 months to 31 October 2015 are outlined in the following

table:

|

i)

|

Resource

Consent Compliance (rolling 12 month record)

|

|

|

Ø Discharge to Estuary Permit

|

Not

achieved. Two discharges of raw sewage occurred at Saxton pump station during

this period.

|

|

|

Ø Discharge to Air Permit

|

100%

Compliance

|

|

|

Ø Biosolids Disposal

|

100%

Compliance

|

|

|

Ø Discharge treated

waste

water to land

|

100% Compliance

|

|

ii)

|

Odour Notifications

|

|

|

Ø Past three months

|

Nil.

|

|

|

Ø Last 12 months

|

Nil.

|

|

iii)

|

Overflows

|

|

|

Ø Past three months

|

Nil

|

|

|

Ø Last 12 months

|

Two.

|

|

iv)

|

Speed of

response for maintenance works

|

|

|

In past

three months:

Ø Three call outs for Saxton pump station.

Blockage of duty pump.

Ø One call out related to Songer pump

station.

|

|

|

Ø Response within 30 minutes.

Achieved.

|

|

|

|

|

|

7. Review

of Action Plan Implementation –

2014 Asset Management Plan and 2015/16 Business Plan

The following table indicates the draft

time lines for the individual action items:

|

IP

|

Business Plan Action

|

Target Date

|

Completion Date

|

Comments

|

|

1

|

Review

manuals annually.

|

March

2016

|

|

|

|

2

|

Consolidate

all natural disaster information and review 3 yearly.

|

March

2016

|

|

|

|

3

|

Internal

benchmarking carried out annually.

|

June

2016

|

|

|

|

4

|

Review

risk of contributors leaving NRSBU.

|

June

2016

|

|

|

|

5

|

Review

capacity of treatment components.

|

June

2016

|

|

|

|

6

|

Programme

for pipe inspections.

|

June

2016

|

|

|

|

7

|

Annual

review of contractor performance.

|

Dec

2016

|

|

|

|

8

|

Screen

upgrade.

|

June

2016

|

|

|

|

9

|

Review

secondary sludge separation.

|

Dec

2016

|

|

|

|

10

|

Construction

second sludge storage tank.

|

June

2016

|

|

|

|

11

|

Develop

sludge removal programme.

|

June

2016

|

|

|

|

12

|

Review

effluent discharge management.

|

Mar

2016

|

|

|

|

13

|

Renewal

of effluent discharge permit

|

Dec

2018

|

|

|

|

AP

|

AMP

Action

|

Target

Date

|

Completion

Date

|

Comments

|

|

1

|

Annual

customer survey.

|

Mar

2016

|

|

|

|

2

|

Business

Continuity Plan review.

|

Jun

2016

|

|

|

|

3

|

Consider

benefits of succession planning and how it might be implemented with be

considered once governance issues (TDC and NCC) have been resolved.

|

Jun

2016

|

|

|

|

4

|

Review

of security required at all facilities.

|

Mar

2016

|

|

|

|

5

|

Monitor

sludge levels in ponds and ascertain long term removal and disposal

requirements.

|

Mar

2016

|

|

|

|

6

|

Improve

reporting requirements for asset condition, performance and maintenance from

maintenance contractor.

|

Mar

2016

|

|

|

|

7

|

Implementation

of internal bench marking (using historical data) of NRSBU network, pump

stations, treatment and disposal facilities.

|

June

2016

|

|

|

|

8

|

Develop

Demand Management Policy.

|

June

2016

|

|

|

8. Health

and Safety

8.1 There

have been 2 Health and Safety inductions and 164 visitors to the Bell Island

site over the past three months.

8.2 Only

one Health and Safety incident was raised during the three month period. As a

consequence procedures have been put in place to strengthen the wind stays on

the door to the milliscreen.

9. Financial

9.1 Power

usage at the treatment plant is tracking well under budget. It is expected that

this will continue through to April 2016. This is contingent on pond condition

as well as other wastewater process units.

9.2 Following

the replacement of the duty pumps with the spare duty pumps at the Saxton and Airport

pump stations, the efficiency of the pump stations has returned back to long

term trends.

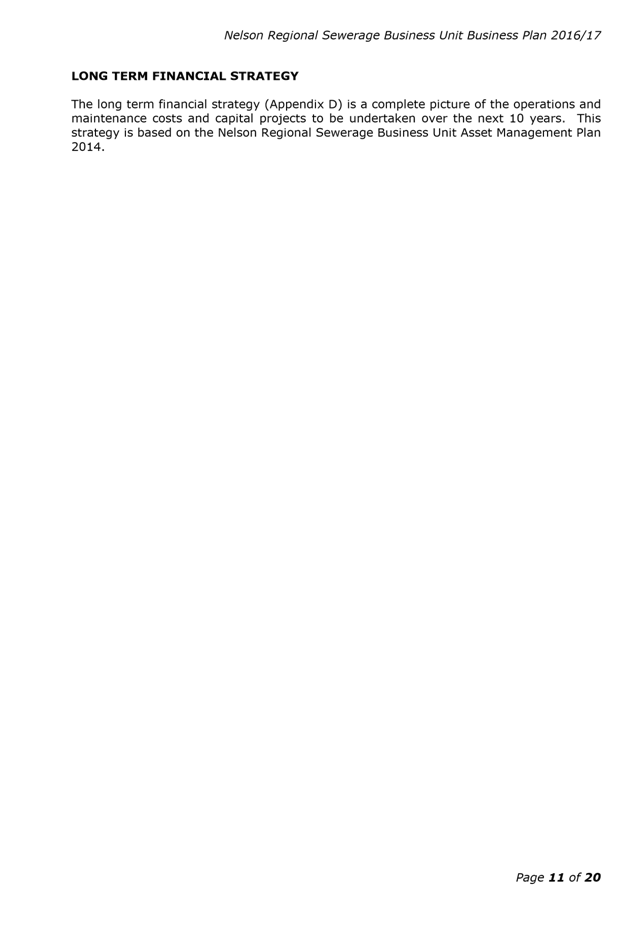

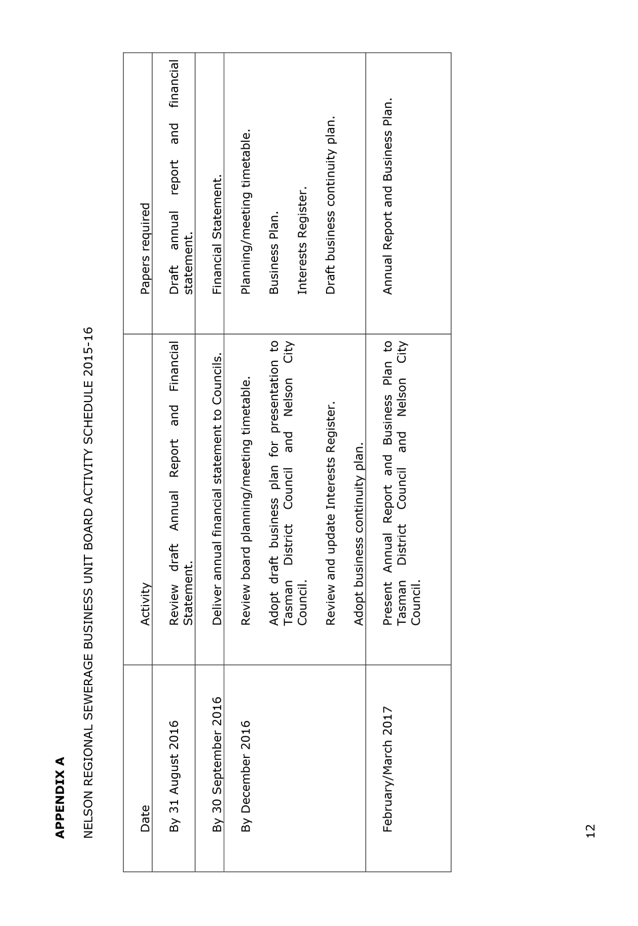

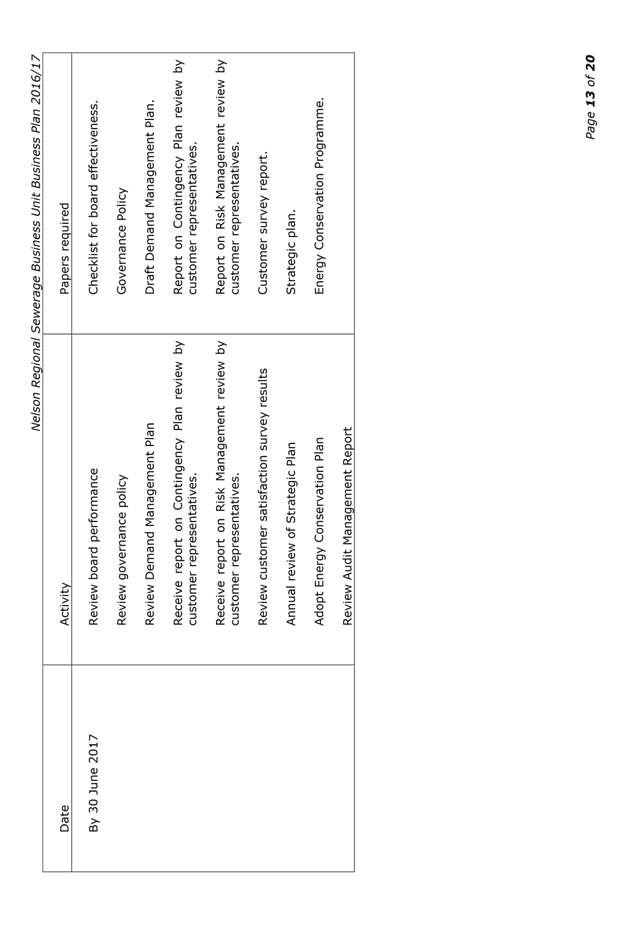

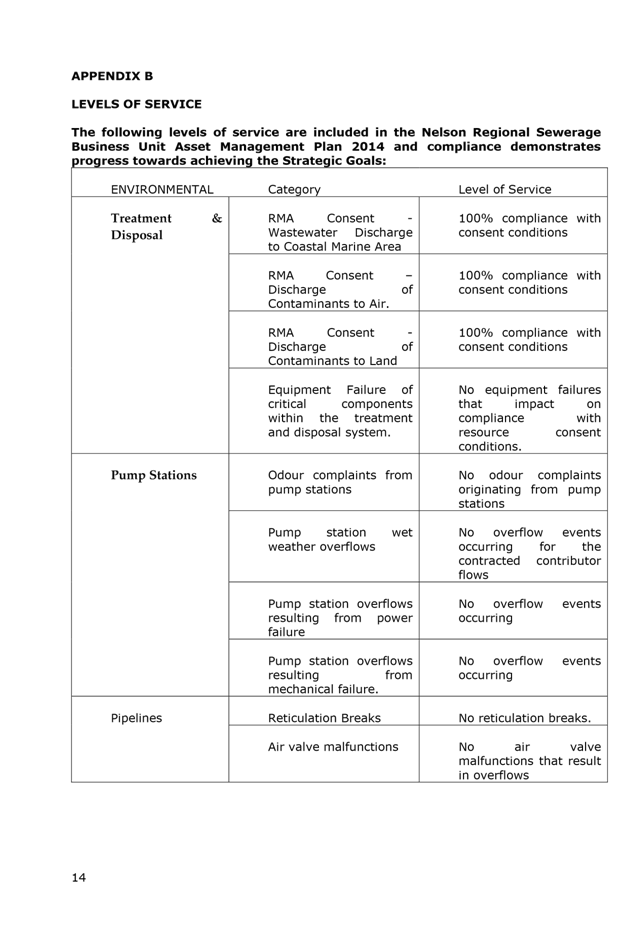

10. Business

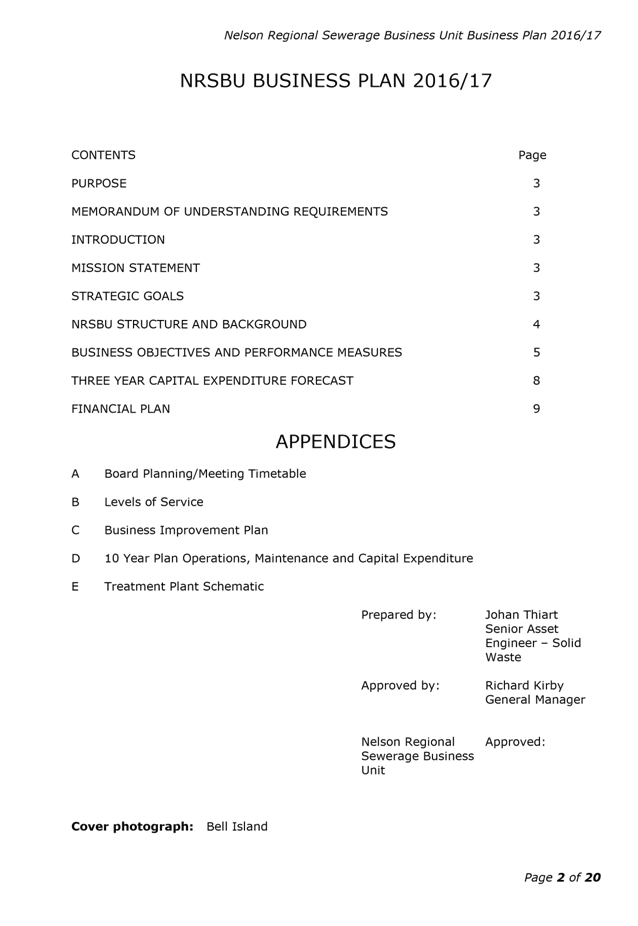

Plan 2016/17

10.1 The Business Plan 2016/17 is appended for the

consideration of the Board.

Richard

Kirby

NRSBU

General Manager

Attachments

Attachment 1: NRSBU

Status Report December 2015

Attachment 2: NRSBU

Draft Business Plan 2016-17

|

|

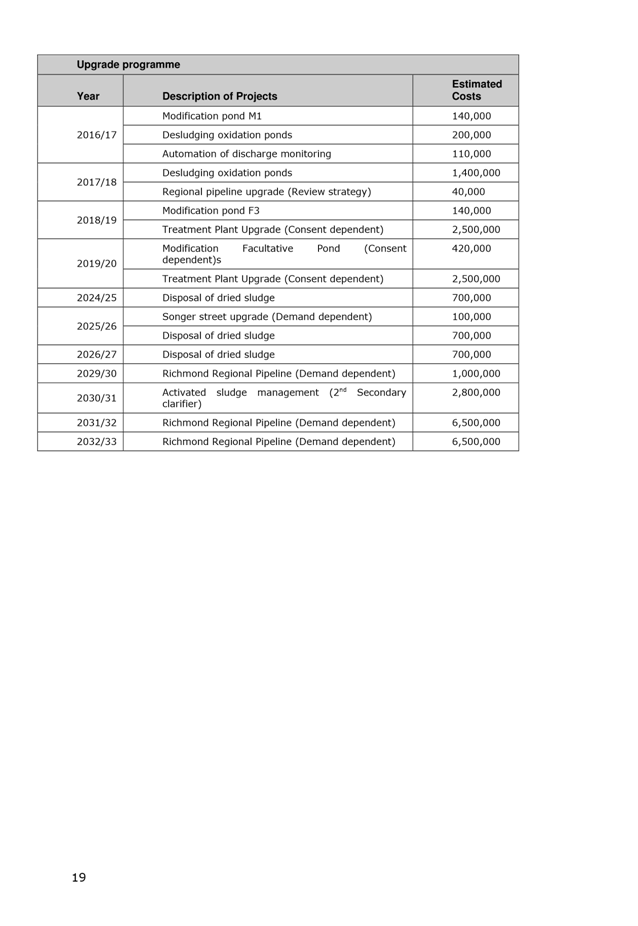

Nelson Regional Sewerage Business Unit

11 December 2015

|

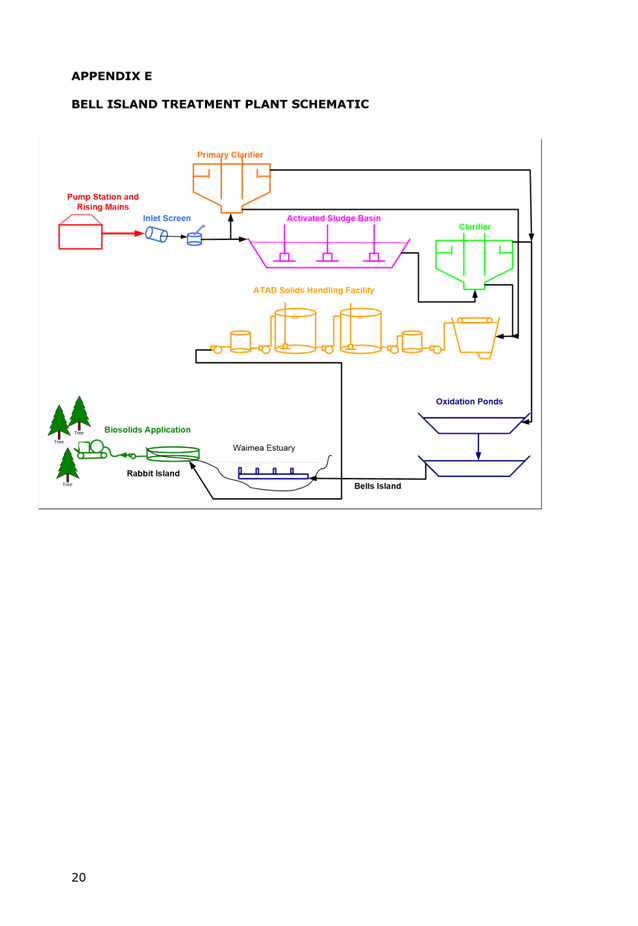

REPORT R5197

NRSBU

Review of Alternative Biosolids Disposal Options

1. Purpose

of Report

1.1 To

review the biosolids disposal options available to the NRSBU in the

event that Rabbit Island is no longer available for this purpose.

2. Recommendation

|

THAT the report NRSBU Review of

Alternative Biosolids Disposal Options (R5197) and its attachment (A1468738) be received;

AND THAT

the current biosolids disposal practice at Bell Island

is economical.

|

3. Background

3.1 The Board has requested a

short report that will quantify the benefits of biosolids application at Rabbit

Island to the owners of Rabbit Island.

3.2 It is considered appropriate

to understand the implications of the loss of opportunity to dispose of

biosolids at Rabbit Island.

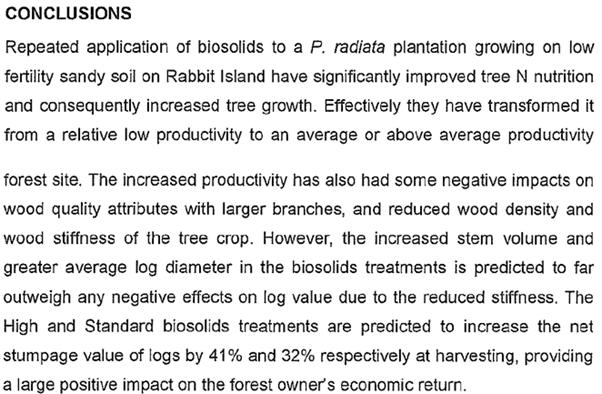

3.3 The improved productivity of

the land resulting from biosolids spraying does not form part of this report,

however it should be noted as being a benefit. (Extract from SCION report

Attachment 1)

4. Rabbit

Island – Biosolids Disposal

4.1 In

the event that Rabbit Island becomes unavailable for biosolids disposal the

NRSBU will have to consider other disposal options.

4.2 Appropriate

alternative biosolids sites for bioslids disposal are limited.

4.3 The

alternatives listed in the table in Clause 5.0 will have to be investigated.

This will require matching sludge treatment processes at Bell Island with the

most appropriate disposal option.

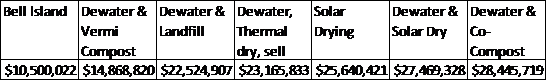

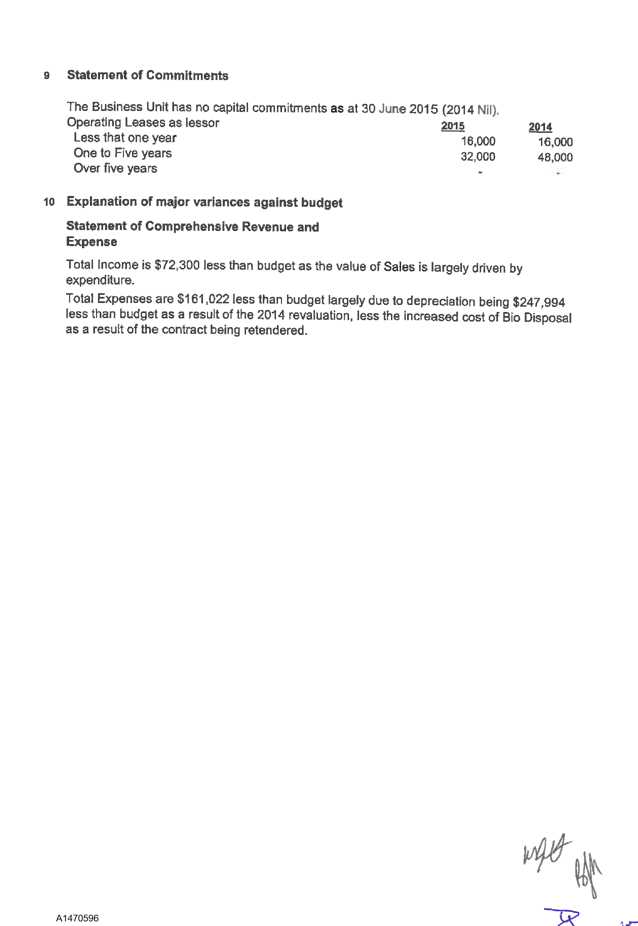

5. Comparison

of seven biosolids disposal systems

5.1 As

part of the exercise input was obtained from OPUS (John Crawford), MWH (Rainer

Hoffman – capacity as wastewater specialist to NELMAC) and ADI (Nathan

Clark – capacity as the process designer of all the major upgrades at

Bell Island since 1998).

5.2 OPUS was commissioned to

research the cost of treatment plants across New Zealand to establish a high

level Net Present Value comparison for different modes of biosolids disposal.

The NPV outcomes from this research is summarised in the following table;

5.3 This

table shows that the Bell Island disposal option (currently sprayed at Rabbit

Island) is the most cost effective. The next most cost-effective is

dewatering and applying the biosolids to a vermiculture composting operation.

5.4 The

environmental benefits of disposing of biosolids on Rabbit Island cannot be

underestimated. It is not only cost-effective but it also has a low carbon

footprint. The alternative disposal processes are likely to have significantly

larger carbon footprints.

6. Implementing

Alternatives

6.1 The additional costs,

economic as well as environmental, associated with the implementation of an

alternative biosolids disposal system at Bell Island could be significant.

6.2 The provision of additional

facultative pond capacity at Bells Island could be an alternative. It could be

brought on line through the construction of another pond or by increasing the

capacity of the current ponds to digest sludge through installation of

additional aeration capacity.

6.3 Additional pond capacity

would also improve the resilience of the treatment facilities at Bell Island,

increase capacity and improve quality of treated wastewater.

6.4 The integration of another

pond will also provide further opportunity to divert load away from the

activated sludge process that can create savings in terms of the use of

electricity and use of chemicals at Bell Island.

6.5 ADI reported that the

facultative pond option would assist in the management of biosolids through

diverting solids from the biosolids system, and improve the breakdown of solids

at medium capital cost, and at low operational cost.

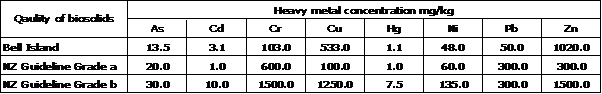

7. Biosolids

Dewatering

7.1 Input

received from MWH shows that it is feasible to develop a solar drying facility

for the dewatering of biosolids at Bell Island. It is reported that dryness of

between 70% and 80% is achievable.

What

can the biosolids be used for

7.2 The

concentration of heavy metals in biosolids produced at Bell Island limit the

use of the biosolids. The following table compares the typical biosolids

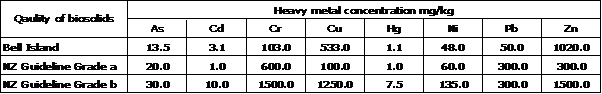

produced at Bells Island with the New Zealand Guidelines;

7.3 The

Bell Island biosolids is classified as Grade Ab and therefore has a restricted

use requiring specific consents for discharge.

7.4 There

is potential to reuse the biosolids produced at Bell Island through

modification. Co-composting of biosolids and other organic material such as

timber waste products has the potential to improve the quality of the biosolids

produced to Grade Aa and will allow the use of the biosolids as an organic

fertiliser.

8. Conclusion

8.1 The Bell Island biosolids

disposal system is the most cost-effective alternative and with its low carbon

footprint, should be retained by the NRSBU as the preferred disposal

alternative.

8.2 That the NRSBU work with the

Tasman District Council to retain all or as much area as possible of Rabbit

Island for the purpose of spraying biosolids.

Richard

Kirby

NRSBU

General Manager

Attachments

Attachment 1: SCION economic

analysis of Beneficial use of biosolids at Rabbit Island

|

|

Nelson Regional Sewerage Business Unit

11 December 2015

|

REPORT R5204

NRSBU

Risk Profile - Impacts of Contributor Exit

1. Purpose

of Report

1.1 To

consider the risk to the Owners, NRSBU and Contributors if a contributor

exits the Trade Waste Agreement.

2. Recommendation

|

THAT the report NRSBU Risk

Profile - Impacts of Contributor Exit (R5204)

be received.

|

3. Background

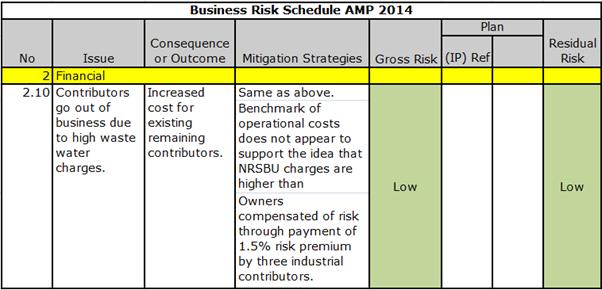

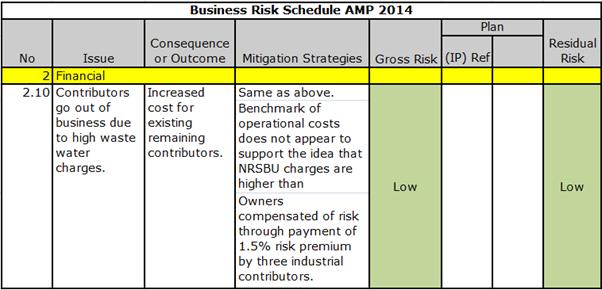

3.1 The impact arising from a

contributor exiting its Trade Waste Agreement has been listed as a business

risk in the current Asset Management Plan.

3.2 While

the risk of a contributor going out of business is considered to be low it has

become apparent that contributors are actively looking at modifying their

discharge flows and/or loads to decrease their trade waste levies.

3.3 Contributors have indicated that their companies are price sensitive and

that strategic investment decisions are being affected by the trade waste

levies currently levied by the NRSBU.

4. Discussion

Affect

on stakeholders if one contributor exists the trade waste agreement

4.1 Currently

should a contributor exit their trade waste agreement with the NRSBU their

capacity allocation would revert back to the NRSBU. It would then be available

for other contributors to purchase.

4.2 If

none of the current contributors want to purchase increased capacity then the

surplus capacity will become the responsibility of the two Council owners of

the NRSBU.

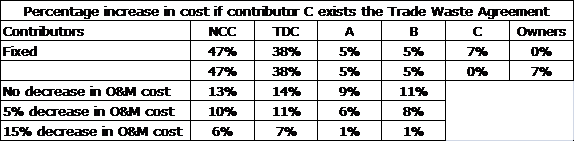

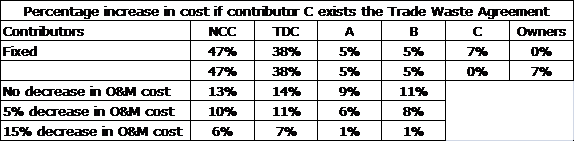

4.3 The

operation and maintenance cost will be then shared by the remaining

contributors. The following table outlines the impact on the fixed costs

(capacity related) and the consequential allocation of operating costs to the

other contributors should a contributor exit their trade waste agreement;

Increased

wastewater treatment capacity

4.4 Where

any industrial contributor exits the agreement there should be a change in load

to the wastewater treatment plant. Dry weather flows into the plant would

reduce moderately, however the loads could reduce more significantly. This

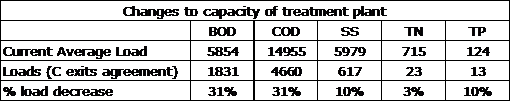

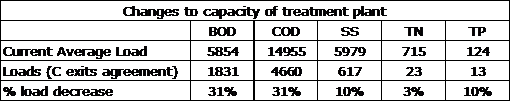

could increase available treatment capacity at Bell Island.

4.5 The

changes in loads to the plant will provide a range of opportunities to the

NRSBU to decrease costs to the remaining contributors or to improve

environmental outcomes. The following table shows the potential decrease

in loading should contributor C cease as a contributor;

4.6 The decrease in load

resulting from an exit by industrial contributor C could generate savings on

power usage at the treatment plant (Estimated 30% = $174,000 per annum) and the

spraying of biosolids at Rabbit Island. (Estimated = $60,000 per annum)

4.7 The decrease in direct

operational costs resulting from the exit of one of the industrial contributors

will have a minor effect on the cost to the remaining contributors.

4.8 Should a contributor exit

their trade waste agreement, thereby releasing capacity, then additional

capital investment to increase capacity could be deferred beyond 2025.

Other

Mitigation Measures

4.9 Optimised replacement could

result in a decrease in annual depreciation which would reduce trade waste

levies to contributors.

4.10 Decreased

sludge harvesting resulting from the exit of an industrial contributor could

allow for the removal of:

· One

of the three ATAD trains,

· The

heat exchanger from the renewal programme.

5. Conclusion

5.1 Although the exit of one of

the industrial contributors from their trade waste agreement will have an

impact, it is considered that it will not have a dramatic impact on trade waste

levies to the remaining contributors and the NRSBU owners.

Richard

Kirby

NRSBU

General Manager

Attachments

Nil

|

|

Nelson Regional Sewerage Business Unit

11 December 2015

|

REPORT R5208

NRSBU

Bells Island Wastewater Treatment Plant; Review of Automated Process Control

and Influent Load Monitoring

1. Purpose

of Report

1.1 To review the need for

automated process control and improved influent load monitoring at the Bell

Island Wastewater Treatment Plant.

2. Recommendation

|

THAT the report NRSBU Bells

Island Wastewater Treatment Plant; Review of Automated Process Control and

Influent Load Monitoring (R5208)

be received;

AND THAT

an S::can unit be procured from DCM Process Control and

installed at a cost not exceeding $95,000.

|

3. Background

3.1 The NRSBU Business Plan

2015/16 includes an ‘automation of process monitoring’ project with

a budget of $110,000 within the upgrades funding of $1,235,000.

3.2 It was intended that

this project consider not only automated process control, but also improved

load monitoring and the identification of extraordinary waste streams.

3.3 When this upgrade was

considered by the NRSBU it was advised that a business case would be developed

based on the outcome of automated load monitoring assessment. It was

proposed that this assessment be carried out under the NELMAC contract in

developing the model for the treatment plant processes.

4. Automated

Load Monitoring Assessment

4.1 Due to difficulties in

assimilating sufficient information on the various influent parameters and the

consequential treatment processes, it has been decided that an automated load

monitoring assessment would have sufficient uncertainty rendering it not

cost-effective. Instead a static model has been developed based on

existing influent load monitoring information.

5. Current

load monitoring

5.1 The influent

constituents to Bell Island are monitored based on daily flow proportional

sampling. The daily samples are analysed for COD and suspended solids by

NELMAC in the Bell Island laboratory.

5.2 Once a week the samples

are analysed for TBOD5, COD and Total Suspended Solids (TSS) at a

registered laboratory.

5.3 Once a month inlet

samples are analysed for Total Nitrogen and Total Phosphorous at a registered

laboratory.

5.4 Samples are also

programmed to be taken daily at the contributor points of discharge and kept

for one week in a deep freeze at Bell Island to allow for testing for toxins

should issues be observed at the treatment plant.

5.5 Each month four

consecutive daily samples taken from the contributor points of discharge are

randomly selected to determine the trade waste levies for that contributor for

that month.

5.6 Recently there have been

questions raised by contributors regarding the veracity of sampling results at

their points of discharge.

5.7 Correspondingly loading

spikes have been observed during spot sampling of the influent at the Bell

Island Wastewater Treatment Plant.

5.8 With these

uncertainties, it is necessary that a more rigorous monitoring regime be

implemented to restore confidence. It is therefore proposed that improved

monitoring of influent loads to the Bell Island WWTP be implemented that will

identify extraordinary loads, shock loads and to provide more certainty to the

sampling results at the contributors’ points of discharge.

6. Automated

Load Monitoring Proposal

6.1 The original intention

was to purchase equipment to provide automated process control, as well as

improved load monitoring and the identification of extraordinary waste

streams. At this stage it is not intended that the NRSBU progress with

automated process control but instead implement automated continuous load

monitoring.

6.2 Automated load

monitoring will help provide more accurate and timely information on load

composition which will deal with the uncertainties outlined in clause 5.

In addition influent load concentrations will be available for analysis at 2

minute intervals for all the parameters currently tested for at monthly

intervals.

6.3 The automated load

monitoring equipment will gather information that can then be used to:

· Constantly

calibrate the static model of the wastewater treatment process;

· Improve

the understanding of waste composition that will be useful in developing future

demand management strategies;

· Assist

in identifying sources of spike loadings and extraordinary waste components;

· Improve

the management and operation of the treatment plant.

6.4 It is therefore proposed

that the equipment needed to undertake this task be procured with the funding

allowed for in the Business Plan 2015/16. The equipment proposed is a

spectrometer.

7. Automated

Load Monitoring Equipment - Spectrometer

7.1 The spectrometer

(S::can) has been developed by DCM Process Control. It provides robust

analysis, requires low maintenance and has the mobility to be transported

around the wastewater network in addition to being based at the wastewater

treatment plant.

7.2 The S::can has been

developed as a modular unit and can be upgraded to record additional wastewater

parameters if required. It provides real time data on the concentrations

of standard wastewater parameters.

7.3 The S::can will be able

to;

· Identify

shock loading trade waste discharges that could disrupt the treatment process

at the treatment plant. Trade waste contributors have distinct spectral

markers so the data gathered could identify the source of any shock loads and

extraordinary loads;

· Provide

data that can be used to calibrate the wastewater treatment plant model and to

simulate plant processes more accurately;

· Identify

trade waste discharges that should be controlled and allow the NRSBU to target

source reduction through the Councils’ Trade Waste Bylaws;

· Take

samples where extraordinary loads are monitored. The S::can can activate

alarms so that the operators can process the samples in a prompt and timely

manner.

7.4 The NELMAC wastewater

specialist has also endorsed the use of this equipment.

7.5 Watercare Ltd has advised that it uses several of these

S::can units at their treatment plant and have found them particularly useful

for monitoring trade waste discharges and

process control of specific wastewater process units within the treatment

plants. Watercare Ltd also reported that the units are low maintenance

and reliable.

7.6 At this stage the NRSBU

is proposing to only install a “spetro::lyser” module in the S::can

unit. Once the operators are comfortable using the information from it

and if it is warranted, the NRSBU could consider implementing the

“ammo::lyser III pro” module in the S::scan unit.

7.7 The information from the

S::can unit will be available on a webserver and available for analysis by

operators, the wastewater specialist and NRSBU officers.

8. Spectrometer

Procurement Details

8.1 The S::can unit costs

$86,961.73 (plus GST) to purchase. This includes installation, training,

12 months analytical support and 12 month modem fee. This cost is subject

to exchange rate fluctuations.

8.2 The cost of connecting

the system to SCADA network is estimated at $2,500 (plus GST).

8.3 The installation of the

unit would reduce and maybe eliminate the need to collect and freeze daily

samples of influent. This would potentially accrue of up to $65,000

annually in operational costs. This saving alone proves a valid business

case and in addition the benefit of more certainty in other sampling results.

9. Conclusion

9.1 The procurement of an S::can unit will improve the

operational management of the NRSBU activities. It will assist with the

identification and management of trade waste discharges and provide reliable

information to improve the treatment plant modelling capacity and potentially

save a significant amount on operational costs.

9.2 The S::can unit will improve the ability of the NRSBU

to identify extraordinary waste discharges and allow for the identification of

trade waste customers by the two Councils that need to be managed through trade

waste bylaws.

Richard

Kirby

NRSBU

General Manager

Attachments

Nil

|

|

Nelson Regional Sewerage Business Unit

11 December 2015

|

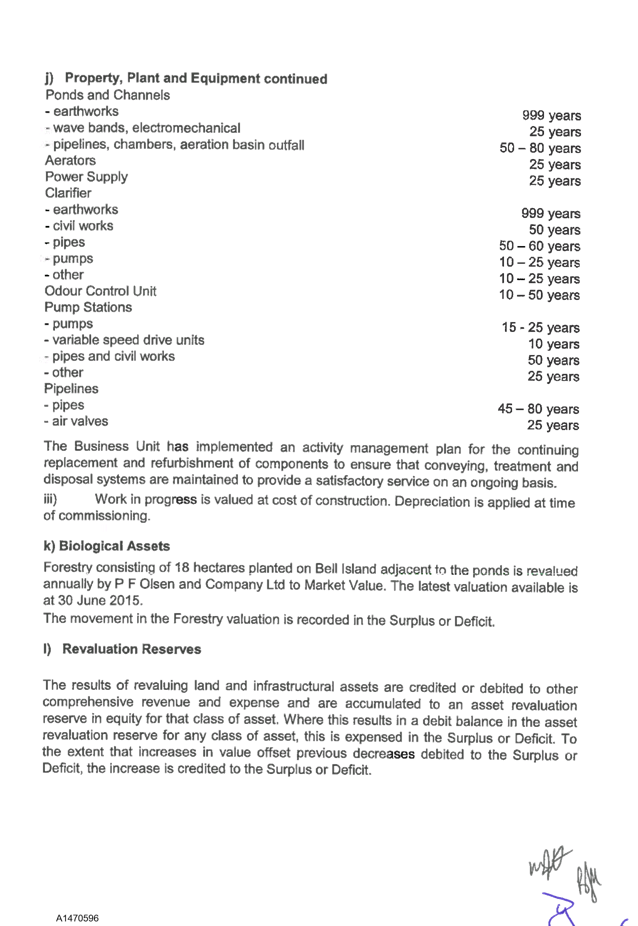

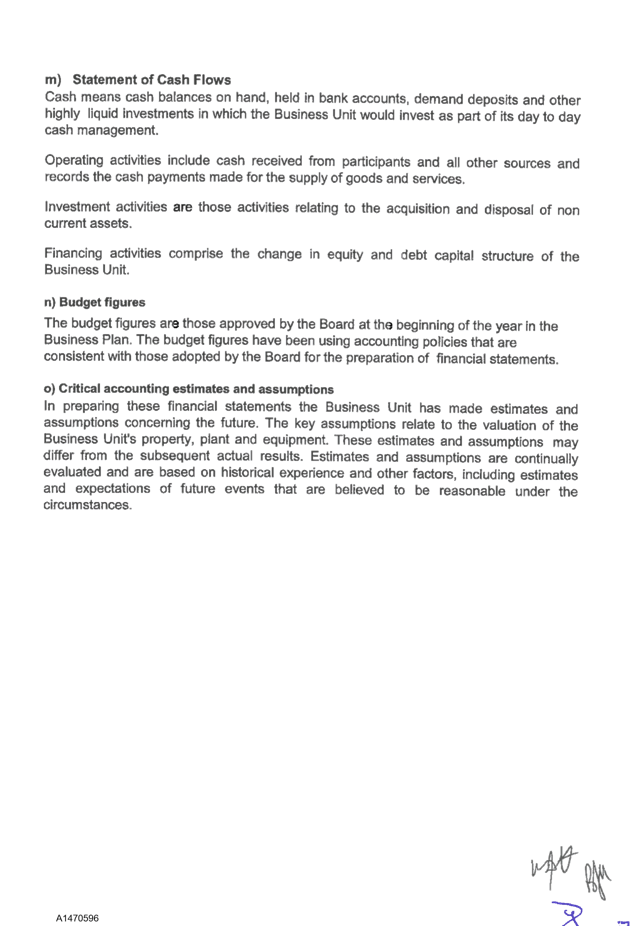

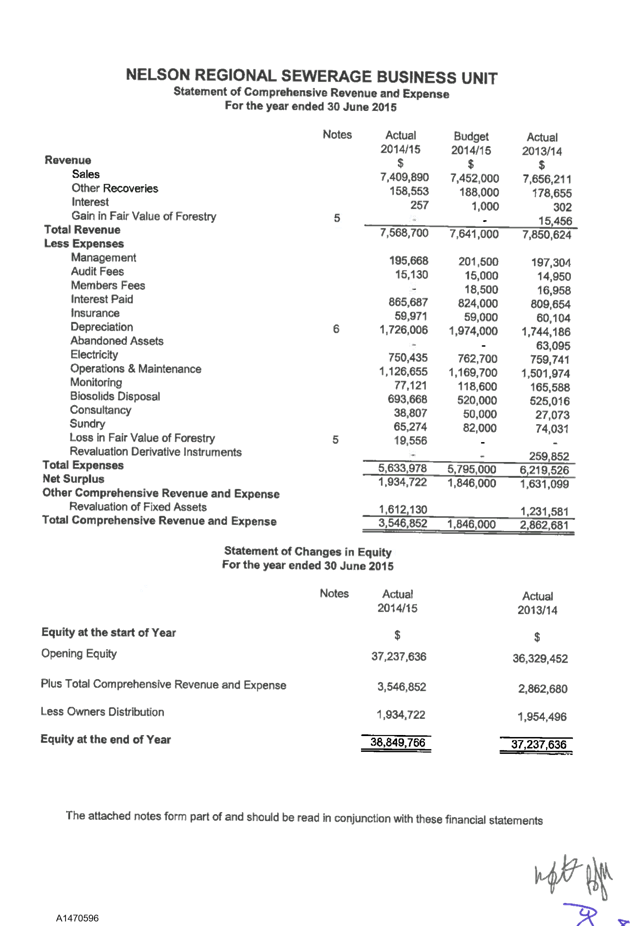

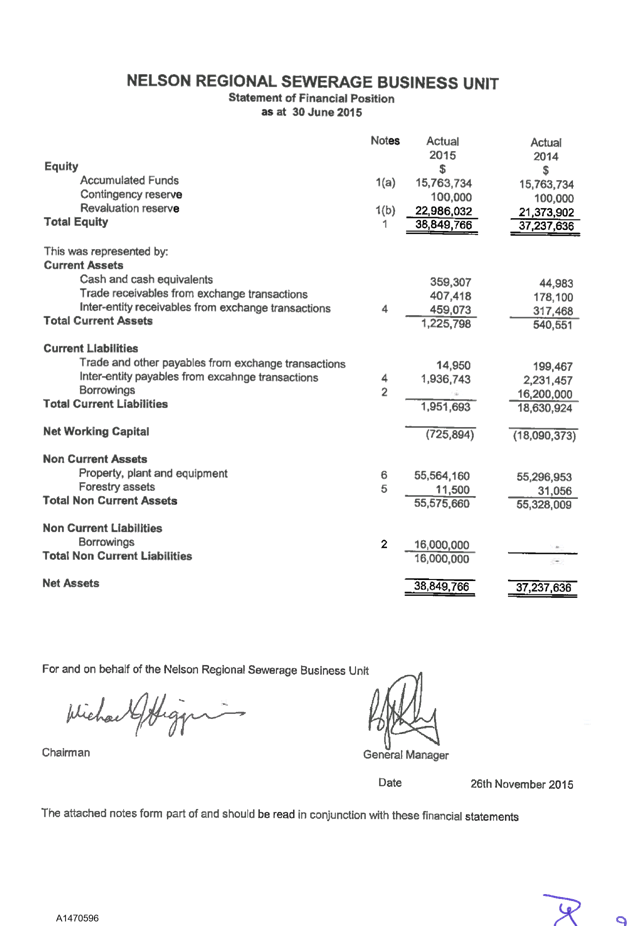

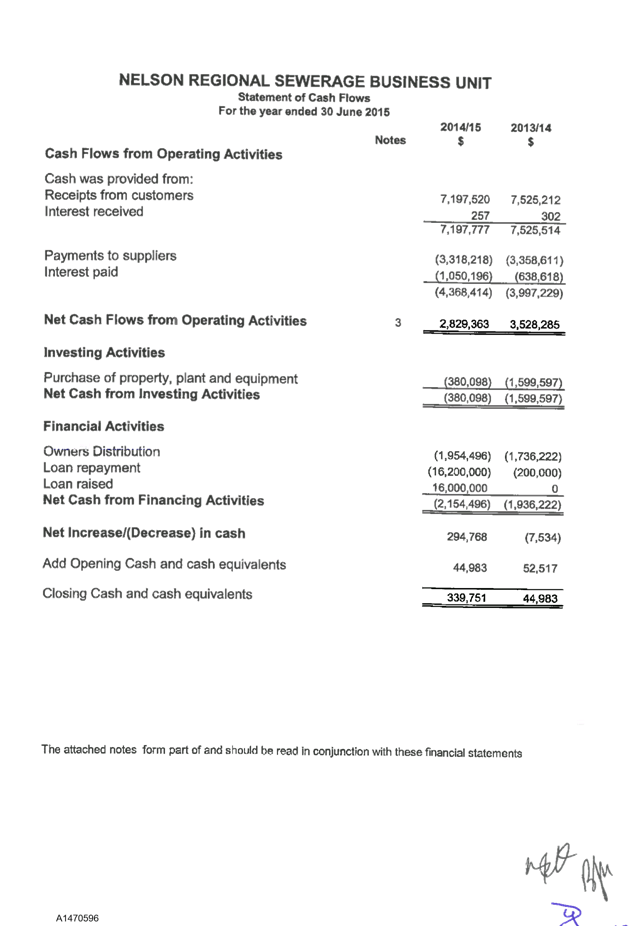

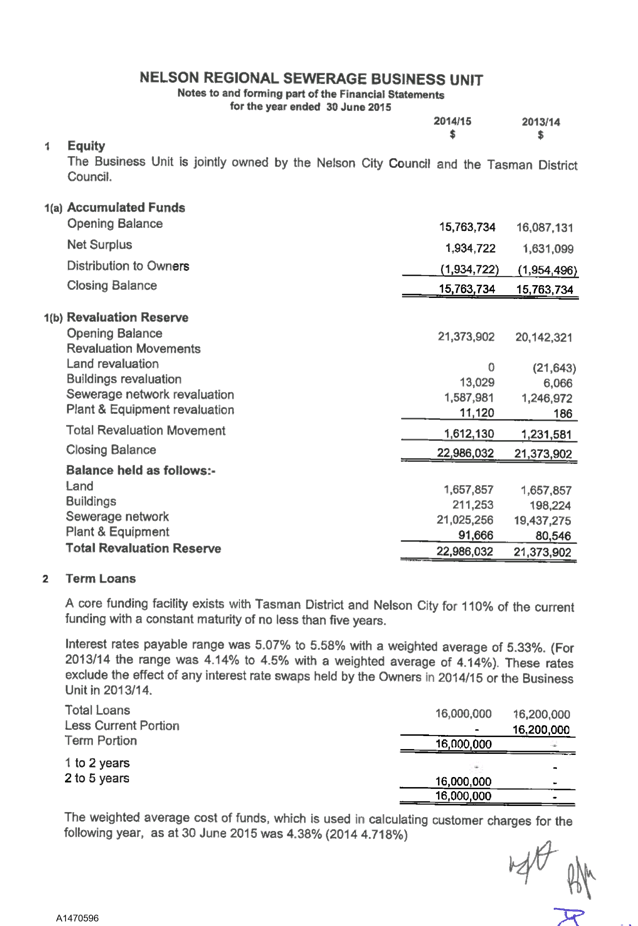

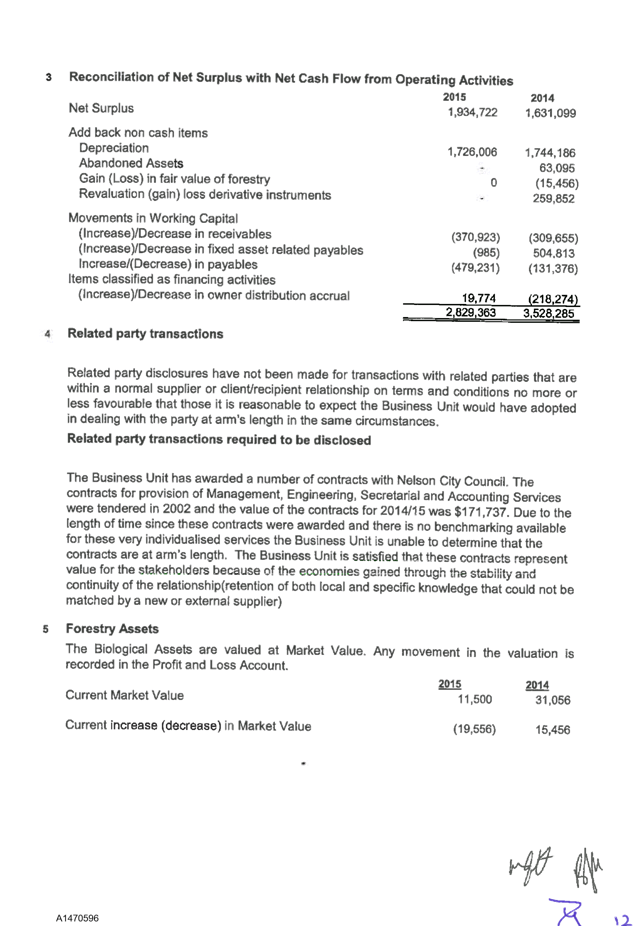

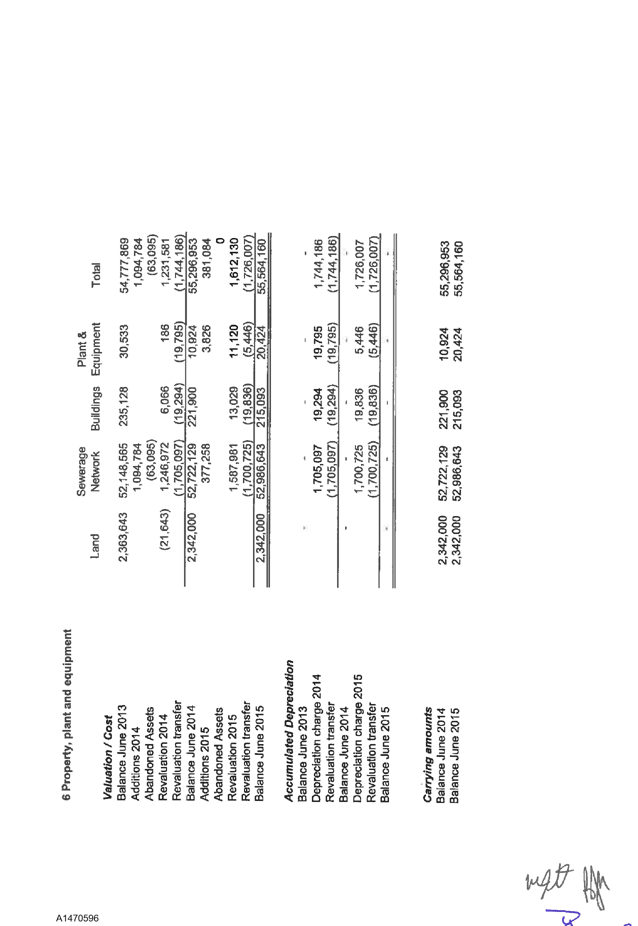

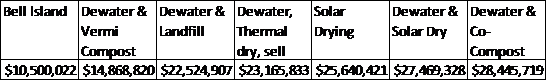

REPORT R5237

Audited

Financial Statements

Attached for information is the Audit letter and approved

financial statements for the year ending 30 June 2015.

Shailey

McLean

Administration

Adviser

Attachments

Attachment 1: A1470592 -

Nelson Regional Sewerage Business Unit Auditors Report 30 June 2015

Attachment 2: A1470596

- Nelson Regional Sewerage Business Unit Signed Financial Statements 30 June

2015